Measurement targets or so-called reference points are often placed on the component surface to be scanned before the 3D scan. The points are used to combine the individual scan images into an overall scan of the complete component and are thus often essential for accurate scan data.

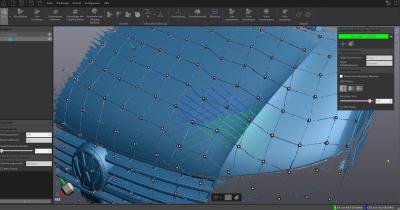

The scanning of large component parts such as engine hoods is now becoming even quicker thanks to a net of measurement targets. The Target-Net by AESUB is laid over the object to be scanned and, just like that, reference points are provided across its whole area. The 3D scan process can start immediately. The target net is thus an efficient alternative to the adhesive dots used in the past, which had to be glued on individually and then laboriously removed again after the measurement.

300 measurement targets

The measurement targets are distributed uniformly at intervals of approx. 100 millimetres across the entire Target-Net. The Target-Net itself measures 1500 x 2500 millimetres and has in total approx. 300 measurement targets. Thanks to the high measurement target density, several scans can be performed very quickly from different perspectives.

Target-Net for metallic and non-metallic parts

For metallic parts, a net with magnetic measurement targets is available; measurement targets hold securely to the surface. With non-metallic parts, e.g. made from stone or plastic, the Target-Net is stretched across them or, depending on the material or surface, fixed with optionally available suction pads. The reference points “float” approx. 10mm above the surface. The individual mesh threads are either not even detected by the scanner or can be cut out with a few clicks in post-processing using suitable software.

Net can be reused

The Target-Net is handy, can be packed away quickly and is easy to transport. Since the net can be reused almost indefinitely, this significantly reduces the amount of consumables required.

Special sizes, e.g. 8000x12000 millimetres, can be manufactured on request.

Retro-reflective reference points

Currently, the Target-Net is equipped with 6mm retro-reflective reference points. In the future there will also be a version with 3mm points. On request, Target-Nets with non-reflective points can also be produced.