The world premiere of SprutCAM X 17 took place at the first SprutCAM X World conference in the company's history.

On June 13, 2023, the first day of the SprutCAM X World conference currently taking place in Limassol, Cyprus, SprutCAM Tech announced the upcoming release of the 17th version of SprutCAM X and SprutCAM X Robot. The company revealed breakthrough innovations and key features of the new version, which cover all areas of the software: user interface, overall product design, new functionality, streamlining of frequently used operations, further development of existing applications and release of new applications in the SprutCAM X ecosystem.

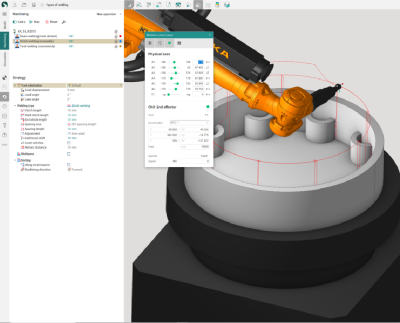

The evolution and ehnancement of SprutCAM X user interface will continue. "Less interface is better" sounds simple in theory, but it becomes an extremely challenging task when dealing with CAM software with thousands of features. For many years we have been striving to keep the UI as simple and lightweight as possible. In the last couple of years, we started to think about how to make the interface feel natural and comfortable to the human eye. In version 16, we introduced a completely new color palette inspired by natural colors such as sea, sand, sun, rocks, and earth. These colors were harmonized and integrated into the user interface. In SprutCAM X 17 we have made evolutionary changes, improving color balance for long working sessions and ensuring a consistent interface across different second level windows.

The new version of SprutCAM X will enhance and optimize the overall product design, including the following features:

- Intuitive hints and interactive smart hints to quickly navigate parameters.

- One window for everything.

- Handy availability of everything the user needs.

- Clean and simple design.

- Consistent workflow.

With its lightweight interface, intuitive design and machine-aware programming technology, SprutCAM X 17 becomes extremely easy to learn and use as a CAD/CAM software.

Here are the additional features in the latest version of SprutCAM X that deliver enhanced workflow efficiency, safety, convenience, and cutting-edge technologies:

- Multi-project workflow: Provides a streamlined workflow for improved time efficiency and easy reuse of similar approaches across multiple projects.

- Snapshots: Increased safety while working on machining projects and quick recovery to the desired project state.

- Machine Setup File: Enables easy and quick transfer of machine digital twins, settings, and tools using ready-made templates.

- Machining Report: Generates reports with only relevant content, swiftly produces reports, and provides high-quality images.

- Ency: SprutCAM X AI virtual assistant, a first in the CAM industry, opens new learning opportunities for G-code proficiency.

SprutCAM X 17 brings a variety of exciting features to cater to the needs of the new generation of makers and robotics enthusiasts.

When it comes to improving the existing functionality, we give priority to analyzing the usage statistics in SprutCAM X. With the latest version, CNC machine and robot programmers will experience increased comfort, speed and ease in their daily work. You will notice these improvements while performing routine operations in SprutCAM X 17 and SprutCAM X Robot 17, including:

- Roughing waterline

- Undercut waterline for 3-axis machines

- Point Pick and Place

- Redundant axes optimizer improvements

- Arbitrary machine parameter control using a map

- Boundaries of periodic axes

- Approach/return for TCPM-enabled operations using Local CS

- 5-axis Solid Simulation

SprutCAM X is more than just a CAD/CAM software, it represents a whole universe of digital manufacturing. In addition to the release of SprutCAM X 17, users will also receive updated versions of the following applications:

- Built-in parametric CAD module: This module will see improvements in UX/UI, performance, and stability. Improvements will be made to fillets, chamfers, surface inclination, array features, combining parts using Boolean operations and new sketching features, among others.

- MachineMaker: This application serves as a digital twin builder for robotic cells and CNC machines. It will now support milling machines with optional axes, turn-mill machines, and Swiss-type machines. The introduction of a new interactive simplifier will greatly reduce the amount of routine work.

- New Online Project Library: This cloud-based platform will facilitate collaboration and project sharing among SprutCAM Tech developers, SprutCAM X partners, and SprutCAM X customers.

- Exciting New Software Product: During the exclusive showcase at the SprutCAM X World conference, SprutCAM Tech demonstrated a completely new software product to its partners and conference attendees. This revolutionary software will be announced to the public in the nearest future. It implements an entirely new workflow between CNC programmers and CNC operators at the shop level.

Andrei Kharatsidi, co-founder of SprutCAM Tech: “Experience the future of CAD/CAM with SprutCAM X 17, our most powerful and functional version yet, to be released in September 2023. Get ready to unlock a new level of capabilities and possibilities for your projects”.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided design ( CAD)

computer-aided design ( CAD)

Product-design functions performed with the help of computers and special software.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- recovery

recovery

Reduction or removal of workhardening effects, without motion of large-angle grain boundaries.

- robotics

robotics

Discipline involving self-actuating and self-operating devices. Robots frequently imitate human capabilities, including the ability to manipulate physical objects while evaluating and reacting appropriately to various stimuli. See industrial robot; robot.

- undercut

undercut

In numerical-control applications, a cut shorter than the programmed cut resulting after a command change in direction. Also a condition in generated gear teeth when any part of the fillet curve lies inside of a line drawn tangent to the working profile at its point of juncture with the fillet. Undercut may be deliberately introduced to facilitate finishing operations, as in preshaving.