Increasing labor shortages, costs, and consumer demands drive the mission-critical need to automate today's manually performed piece-picking tasks in warehouses and beyond. Siemens intends to democratize access to AI-driven robot technology, pushing today’s automation boundaries towards cognitive industrial automation with superior flexibility and empowering more suppliers developing in-house solutions to participate in this emerging opportunity.

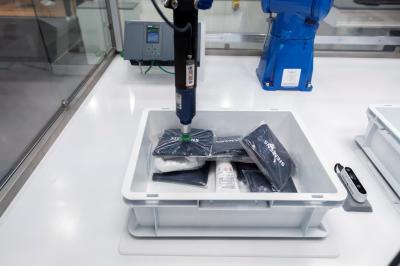

SIMATIC Robot Pick AI (robot skill) is a pre-trained, deep-learning-based vision software for advanced robotics applications like goods-to-robot order bin picking that provides out-of-the-box cognitive performance for selecting robust pick points (6-DoF grasp poses) for arbitrary "unknown" items at runtime.

Especially applicable for items in general e-commerce, e-grocery, fashion, or pharmaceutical retail and is proven in applications worldwide. A specific, less flexible CAD model training by the user is no longer necessary (generic, model-free robot grasping).

Complex use cases with arbitrary items of various shapes, sizes, and packaging can be reliably automated with a pick success rate of over 98% on the first attempt. Two percent is equivalent to the error rate of a human performing the goods-to-person order bin-picking task. Even challenging image-based scenarios, such as tightly packed items or items at the outer rim of the bin, will be accomplished. Changed bin positions and empty containers are detected automatically at runtime. The identified pick points are provided via standard APIs for execution in the user application with any 6-axis robots. In addition, various suppliers' 3D cameras (RGB-D) are supported as sensors (from low-cost to high-definition). Guided commissioning is achievable in less than 20 minutes (after installation and calibration of the 3D sensor). With fast computation times, high pick rates of over 1,000 picks-per-hour (PPH) are achievable - depending on the runtime hardware used.

SIMATIC Robot Pick AI is deployable on IPCs with the Linux operating system and can run even on smaller standard IPCs without a dedicated GPU or AI accelerator. Fast computation times allow high pick rates. A unique, easy integration of our deep learning vision software into the SIMATIC platform and the TIA Portal engineering framework can be achieved by deploying it on SIMATIC IPCs or the SIMATIC S7-1500 TM-MFP. AI-driven robots can contribute to the flexibility to process high variances of objects with different shapes, sizes, and packaging types in dynamically changing situations. SIMATIC Robot Pick AI aims to enable more solutions in line with the market for this emerging market challenge and to accelerate market acceptance of this complex technology by making it easy to access.

Contact Details

Related Glossary Terms

- calibration

calibration

Checking measuring instruments and devices against a master set to ensure that, over time, they have remained dimensionally stable and nominally accurate.

- computer-aided design ( CAD)

computer-aided design ( CAD)

Product-design functions performed with the help of computers and special software.

- reaction injection molding ( RIM)

reaction injection molding ( RIM)

Molding process that allows the rapid molding of liquid materials. The injection-molding process consists of heating and homogenizing plastic granules in a cylinder until they are sufficiently fluid to allow for pressure injection into a relatively cold mold, where they solidify and take the shape of the mold cavity. For thermoplastics, no chemical changes occur within the plastic, and, consequently, the process is repeatable. The major advantages of the injection-molding process are the speed of production; minimal requirements for postmolding operations; and simultaneous, multipart molding.

- robotics

robotics

Discipline involving self-actuating and self-operating devices. Robots frequently imitate human capabilities, including the ability to manipulate physical objects while evaluating and reacting appropriately to various stimuli. See industrial robot; robot.