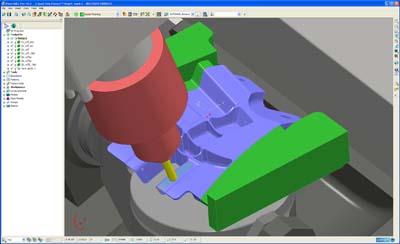

Delcam plc's 64-bit version of its PowerMILL CAM software removes the memory limitations of 32-bit computers, allowing more efficient toolpath generation, especially for companies machining large or complex parts. The new 2010 release also continues to improve user productivity by extending the application of the latest background-processing and multithreading technologies available in recent hardware, according to the company. The combination of these two developments is estimated to reduce calculation times by up to 25 percent, depending on the size and complexity of the part. PowerMILL 2010 also includes more than 50 other major enhancements. These improvements allow faster and easier generation of highly efficient toolpaths for 3- through 5-axis milling. The most obvious change for existing users will be an updating of all the toolpath-creation forms to a new and improved layout. The forms make it easier for new users to find the commands they need, while also giving experienced operators more logical access to the more advanced options. In addition, there is new toolbar that can be pinned to the opening screen for the creation and editing of workplanes. A new series of strategies for roughing and finishing corners has been added. These give more efficient and smoother clearance of these areas, especially when a large tool has been used for roughing initially that has left a significant amount of material in the corner. Rest roughing has been enhanced to give better control over the start points for each segment of the toolpath. This will give substantial savings in overall machining time by minimizing any air cutting. Offset roughing, a popular approach for high-speed machining, has been enhanced so any thin slivers of material can be removed without risking damage to the cutter. These slivers can be left for the final pass when a constant step-over is used for the offset. PowerMILL will now identify these potential problems automatically and adjust the final step-over to give the safest engagement with the material. A number of improvements have been made to give smoother toolpaths for semifinishing and finishing. These minimize the stresses put on the cutter and machine tool, and result in a finer surface finish. They are related to Delcam's patented Race-Line strategies for roughing and act in a similar way across the full extent of the toolpath. For example, sharp changes in direction in 3-D-offset toolpaths are now automatically made much smoother as the tool approaches and leaves, rather than simply introducing an arc at the point of change.

Contact Details

Related Glossary Terms

- clearance

clearance

Space provided behind a tool’s land or relief to prevent rubbing and subsequent premature deterioration of the tool. See land; relief.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- step-over

step-over

Distance between the passes of the toolpath; the path spacing. The distance the tool will move horizontally when making the next pass. Too great of a step-over will cause difficulty machining because there will be too much pressure on the tool as it is trying to cut with too much of its surface area.

- toolpath( cutter path)

toolpath( cutter path)

2-D or 3-D path generated by program code or a CAM system and followed by tool when machining a part.