Hexagon Metrology today announced the launch of PC-DMIS 2012. PC-DMIS focuses on the collection, evaluation, management and presentation of manufacturing data to reduce scrap, improve throughput, reduce costs, and build lean manufacturing operations.

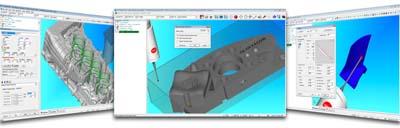

PC-DMIS 2012 rolls out a major new feature, ClearanceCube, to eliminate potential collisions of part and probe. ClearanceCube attaches a protective virtual envelope around the part being measured and guides the probe to avoid that area. The software automatically completes all safety moves so the operator can simply box-select a group of features, then use the Path Optimizer feature to determine the most effective path. Most importantly, the ClearanceCube is assigned to the selected feature, not the plan, which simplifies additions and changes to the inspection routine.

When inspection data is imported into CAD, PC-DMIS 2012 has the ability to "remember" the current translation of assembled components, so the CAD file does not need to be repositioned. Revisions to the CAD file prompt the Change Manager to highlight those design changes automatically. Another enhancement is the new Measurement Strategies for AutoFeatures. Users can now scan planes, circles, cylinders and cones directly from the AutoFeature dialog box with automatic setting of speed, point density, and filtering parameters.

Sortable Features is another addition to the user interface, which provides a fast and easy way to search features by ID, type, program sequence or time in various dialog boxes. The new Summary Mode enhancement adds intelligent, color-coded and symbolic text to avoid the time spent sorting through an inspection report for dimensional compliance. Specialized options are also available for customers with an Optiv vision system or those involved in the inspection of blades.

"PC-DMIS 2012 is built around measurement plan efficiency for greater productivity," states Ken Woodbine, president of the PC-DMIS software division of Hexagon Metrology. "With more than 100 software enhancements, PC-DMIS moves far beyond run-of-the-mill inspection functionality, with automation and customization capabilities that anticipate and solve real world product development and quality control issues."

Contact Details

Related Glossary Terms

- computer-aided design ( CAD)

computer-aided design ( CAD)

Product-design functions performed with the help of computers and special software.

- inner diameter ( ID)

inner diameter ( ID)

Dimension that defines the inside diameter of a cavity or hole. See OD, outer diameter.

- lean manufacturing

lean manufacturing

Companywide culture of continuous improvement, waste reduction and minimal inventory as practiced by individuals in every aspect of the business.

- metrology

metrology

Science of measurement; the principles on which precision machining, quality control and inspection are based. See precision machining, measurement.

- quality assurance ( quality control)

quality assurance ( quality control)

Terms denoting a formal program for monitoring product quality. The denotations are the same, but QC typically connotes a more traditional postmachining inspection system, while QA implies a more comprehensive approach, with emphasis on “total quality,” broad quality principles, statistical process control and other statistical methods.

- vision system

vision system

System in which information is extracted from visual sensors to allow machines to react to changes in the manufacturing process.