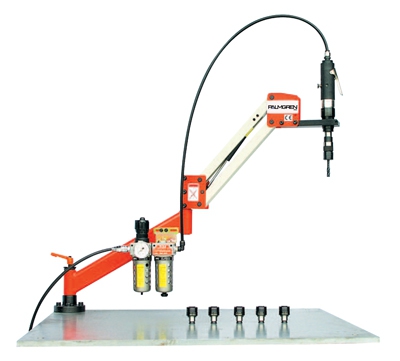

Palmgren's Parallel Arm Tapping tools make tapping fast and easy. The use of a parallel arm tapping machine will generate savings through improved operator utilization, reduced set-up times, reduced material handling and improved material flow. Customers can select the pneumatic tapping arm system, motor and tap holder that best meets their needs.

The Quick-Tap system features a working area reach of 37 inches and is best suited for small and medium size taps. The Shop-Tap is the choice for general-purpose tapping and has a working area reach of 62 inches. With a working area reach of 55 inches, the Production–Tap can be used for a wide range of general purpose to heavy duty tapping. All three have variable mounting capabilities.

Contact Details

Related Glossary Terms

- parallel

parallel

Strip or block of precision-ground stock used to elevate a workpiece, while keeping it parallel to the worktable, to prevent cutter/table contact.

- tap

tap

Cylindrical tool that cuts internal threads and has flutes to remove chips and carry tapping fluid to the point of cut. Normally used on a drill press or tapping machine but also may be operated manually. See tapping.

- tapping

tapping

Machining operation in which a tap, with teeth on its periphery, cuts internal threads in a predrilled hole having a smaller diameter than the tap diameter. Threads are formed by a combined rotary and axial-relative motion between tap and workpiece. See tap.

- tapping machine

tapping machine

Production machine used for high-volume tapping. Offers repeatability, high production rates and reduced tap breakage. Comes in a variety of configurations, including indexing units with multiple tapping spindles. Precise stroke-depth settings and automatic features generally make tapping machines cost-effective.