Advanced Machine & Engineering Co. announces the OTT/JAKOB Analog Position Monitoring System with the Electronic Analog Sensor, which allows you to monitor your drawbar for performance and wear. An electronic analog sensor detects the position and an electronic unit attached to the CNC machine controller transmits the data. This system indicates whether your tools are clamped, unclamped or not present. It can increase tool head accuracy and longevity by monitoring cycles and hours, indicating whether your tools are properly held. Because these units transmit information quickly to the controls, mechanical signal rings with proximity sensors are now obsolete. Negative influences of the mechanical signal rings at higher RPM can therefore be avoided.

Components of the Monitoring System Include:

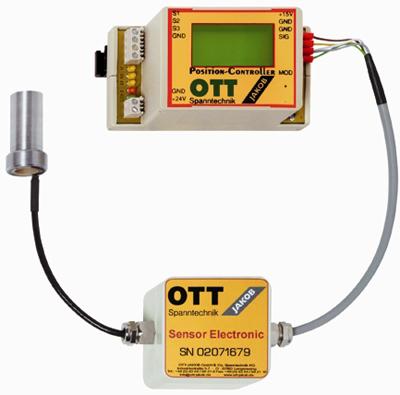

Analog Sensor — The OTT/JAKOB unclamp unit contains a cylindrical, inductive analog sensor consisting of a primary and secondary coil. During clamping or unclamping, as the drawbar connection moves axially through the analog sensor the target ring on the drawbar connection triggers the output signal. The signal increases further, as the target ring enters the sensor, indicating the position. The position is also monitored during the machining process.

Analog Sensor Electronics — The sensor electronics supply the primary coil with constant frequency and amplitude. A demodulator transforms the signal of the secondary coil into a stable DC output signal.

Position-Controller — The position-controller evaluates the current signal and sets the output signals at the adjustable limits. A digital filter compensates existing peak values. The position-controller and a digital readout that also displays operating hours and operating cycles. This makes it a great preventative maintenance tool.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.