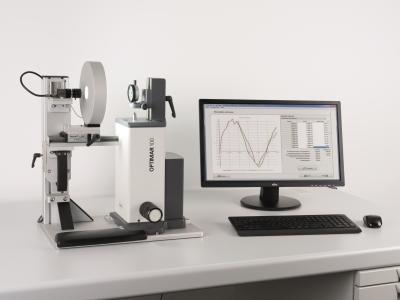

Mahr Inc. announced that it has expanded its OPTIMAR 100, which is for testing dial and digital indicators, test indicators and dial comparators, with image processing for the automated testing of measuring equipment. A new upgrade kit now makes working with the measuring instrument safer and faster: a camera automatically records the indicated values of the test indicators and forwards them to a software for processing. The automated procedure saves time and replaces the exhausting and error-prone reading by the operator.

The hardware and software add-on package provides a cost-efficient way to equip existing measuring stations with OPTIMAR 100 for automated testing. The measuring system, including image processing, is also available as a complete package under the name "Precimar OPTIMAR 100 BV."

The upgrade kit incorporates a USB 3.0 camera for fast image processing, and stable daylight-independent LED illumination along with secure digital identification and reading of digits. The QMSOFT software controls the measuring device, evaluates the camera image of the scale or number display of the test object, compares the values with the high-accuracy internal reference scale and automatically completes the process of calibrating the product under test. The software also makes it possible to create and store test certificates.

The easy operation of the OPTIMAR 100 with image processing speeds up and facilitates the monitoring of the indicators under test. With the auto-recognition of the vision system, more test items and data points can be recorded faster than with conventional manual methods. Because this is a completely automated inspection system, the operator can be more productive in other operations while the OPTIMAR 100 automatically completes the calibration process. This makes indicator inspection much more economical.

Contact Details

Related Glossary Terms

- calibration

calibration

Checking measuring instruments and devices against a master set to ensure that, over time, they have remained dimensionally stable and nominally accurate.

- vision system

vision system

System in which information is extracted from visual sensors to allow machines to react to changes in the manufacturing process.