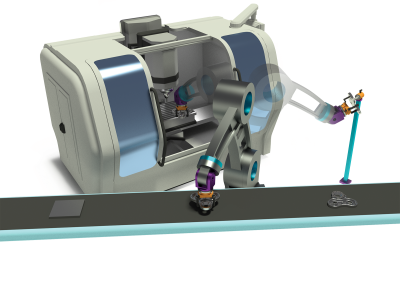

For years, OCTOPUZ has provided the robotics market with an intelligent offline programming and simulation solution ideal for a wide range of industrial robots including KUKA, FANUC, ABB, and Yaskawa Motoman. OCTOPUZ 2.1 redefines the standards in offline robotic programming by offering a simplified approach to solving toolpath trajectories. The new OCTOPUZ PathFinder suite of tools, automatically identifies and solves limits and errors within the program.

OCTOPUZ 2.1 defies the common misconception that OLP is complicated by making complex path creation, simple. With PathFinder, users will be able to achieve a desired path based on OCTOPUZ path intelligence and/or manual user input resulting in more efficient programming.

PathFinder is comprised of seven tools, two of the key tools being: PathAnalyzer and PathSolver. PathAnalyzer will automatically review original toolpaths while detecting and identifying collisions joint limits, reach limits and singularities. Using the generated report, users can quickly self-resolve issues or allow OCTOPUZ to automatically solve on behalf of the user. PathSolver will leverage the PathAnalyzer tool to identify limitations and systematically resolve errors and present the ideal toolpath to the user. Once the process is completed, the new toolpath can be accepted and is ready to be uploaded to the robot.

In addition to the two key tools, PathFinder also includes additional tools designed for Auto Configurations on CAM Import, Error Visualization, Targeted Error Resolution, Foundational Reference Point Assignment and Simplified External Axis Configuration.

With the release of OCTOPUZ 2.1, PathFinder users can now easily import CAM paths, and with a simple click of a button, generate a robot path which is clear of limitations and singularities. By leaving the complicated aspect of OLP to OCTOPUZ, users can spend more time manufacturing and less time programming.

Contact Details

Related Glossary Terms

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- robotics

robotics

Discipline involving self-actuating and self-operating devices. Robots frequently imitate human capabilities, including the ability to manipulate physical objects while evaluating and reacting appropriately to various stimuli. See industrial robot; robot.

- toolpath( cutter path)

toolpath( cutter path)

2-D or 3-D path generated by program code or a CAM system and followed by tool when machining a part.