Emuge Corp. has announced the introduction of MultiTAP-Form, a high-performance forming tap designed to deliver performance increases in a wide range of materials including carbon steel, steel alloys, stainless steel, aluminum, copper, brass, and bronze. In lab tests, MultiTAP-Form demonstrated four times the life compared to a leading brand form tap. MultiTAP-Form is also designed to produce threads within both 2B and 3B classes of fit, eliminating the guesswork of calculating H-limits.

"MultiTAP-Form will significantly improve thread quality and boost output while reducing production costs," said Mr. Peter Matysiak, President of Emuge Corp. "One high performance MultiTAP-Form will handle most common materials and applications. MultiTAP-Form also eliminates the need to stock numerous types of taps that are suitable for forming applications."

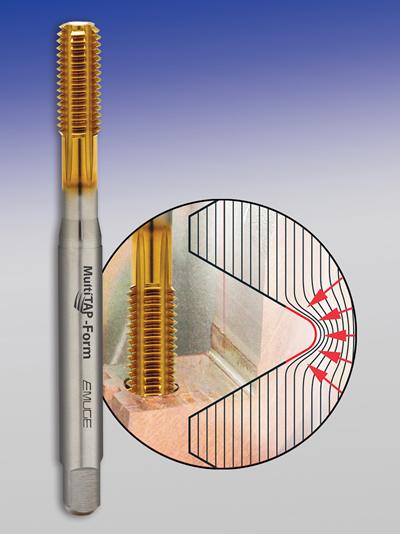

MultiTAP-Form features a new innovative geometric design, a proprietary grade of high speed steel (HSS-E) and is TiN coated for exceptionally long life and versatility. A short chamfer lead of 1.5 to 2 Pitch is ideal for bottom tapping, and lubrication grooves allow coolant flow-to-form action for holes requiring long thread length.

The forming of threads offers many advantages over conventional thread cutting. A formed thread is one where the material has been displaced instead of cut, which provides excellent thread surface quality and increased static and dynamic strength of the thread. Additional benefits include eliminating the risk of poor threads due to axial "miscutting" and the ability to increase tapping speeds.

"Our MultiTAP line is the result of collective years of Emuge's extensive tapping expertise, application research and a challenge the company issued to its engineers to design a multi-purpose tap. Emuge design engineers responded by choosing a select base material, along with special geometry and surface treatment that would work in as many common materials and applications as possible," stated Matysiak.

All MultiTAP-Form Taps are made with Emuge's trademark long shanks which are DIN length, designed for extra reach. Tap sizes include a range for UNC or UNF threads, from #4-40 to 3/8-24 inch sizes, to metric sizes from M4 x 0.7 to M10 x 1.5.

Contact Details

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- pitch

pitch

1. On a saw blade, the number of teeth per inch. 2. In threading, the number of threads per inch.

- tap

tap

Cylindrical tool that cuts internal threads and has flutes to remove chips and carry tapping fluid to the point of cut. Normally used on a drill press or tapping machine but also may be operated manually. See tapping.

- tapping

tapping

Machining operation in which a tap, with teeth on its periphery, cuts internal threads in a predrilled hole having a smaller diameter than the tap diameter. Threads are formed by a combined rotary and axial-relative motion between tap and workpiece. See tap.

- titanium nitride ( TiN)

titanium nitride ( TiN)

Added to titanium-carbide tooling to permit machining of hard metals at high speeds. Also used as a tool coating. See coated tools.