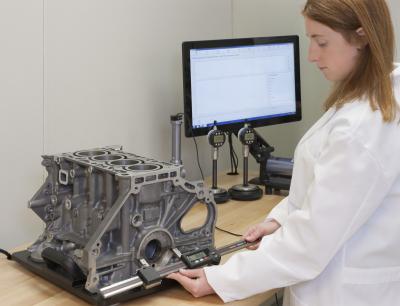

With its broad range of measurement accessories, the new Multimar 25 EWR Digital Universal Caliper from Mahr Federal is a versatile and configurable caliper for ID and OD measurement requirements. Available in four capacities with outside measuring ranges up to 1,250 mm (50 in.), the 25 EWR is an ideal tool for measuring outside and inside dimensions, narrow collars, external and internal tapers, dovetails, grooves, distances between hole centers, for centering shoulders and scribing workpieces.

Unlike standard calipers, both measuring arms of the 25 EWR can be moved along the beam, thus functioning like a beam-gage, and providing well-balanced weight distribution even with small dimensions. The application range can be easily extended by reversing the interchangeable measuring arms. Plus, the digital display is always in the operator‘s line of vision due to the patented mounting fixture of the measuring arms and attachments provided.

But what makes the Multimar 25 EWR so versatile is the range of measuring arms, anvils, mounting attachments and depth stops, which can be configured by the user. Anvils and tips are available in a variety of shapes and configurations, including threads, flat and spherical shoulders, blades and round faces. Depth stops can be set to the exact measuring depth in the horizontal measurement position to provide precise support on the reference plane surface. This improves repetitive accuracy when conducting comparison measurements in the second axis, and when used with a rectangular gage block, can provide accurate depth measurement on cones.

Data output is via USB, Digimatic, Opto RS232C, or wireless, and battery life is about 3 years. The Multimar 25 EWR Universal Caliper provides IP 65 protection for all workshop conditions, and is supplied with battery, instruction manual, hardwood mounting and resting blocks, and a finely crafted wooden case.

Contact Details

Related Glossary Terms

- centering

centering

1. Process of locating the center of a workpiece to be mounted on centers. 2. Process of mounting the workpiece concentric to the machine spindle. See centers.

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- fixture

fixture

Device, often made in-house, that holds a specific workpiece. See jig; modular fixturing.

- flat ( screw flat)

flat ( screw flat)

Flat surface machined into the shank of a cutting tool for enhanced holding of the tool.

- inner diameter ( ID)

inner diameter ( ID)

Dimension that defines the inside diameter of a cavity or hole. See OD, outer diameter.

- outer diameter ( OD)

outer diameter ( OD)

Dimension that defines the exterior diameter of a cylindrical or round part. See ID, inner diameter.