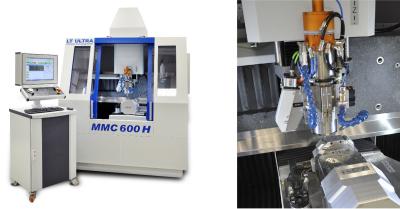

CAD/CAM software specialists ModuleWorks and LT Ultra, specialists for ultra-precision technology, have collaborated on a software solution for ultra-precision milling and turning. Built upon the ModuleWorks 6-axis optics kernel, the new software enhances LT Ultra’s machining platforms with automated workflows for manufacturing diverse parts with nanometer precision.

The ModuleWorks optics kernel has been developed to meet the growing demand for machining increasingly complex free-form geometries with a precision in the nm range. Integrated into the LT CAM product line, it enables LT Ultra to offer flexible solutions for a diverse range of ultra-precision machining applications with automatic toolpath calculation from point clouds, CAD models and analytical functions as well as corrections based on real measurement data. The calculated toolpaths are automatically available for full 3D machining simulation and output via a high-performance CNC posting framework that uses multi-threading for fast generation of large NC programs (up to 50k points per second).

”The ModuleWorks optics kernel allows the full potential of machines to be exploited. The exceptional calculation precision in the nm range and flexible adaptation to our series and custom machines are outstanding. For our customers as well as our own contract manufacturing, we have developed a solution in close cooperation with ModuleWorks that prepares us for the future of ultra-precision machining,” says Dr. Kurt Haskic, Head of Research at LT Ultra.

“Working in close cooperation is the best way to get the most out of our combined technologies and it’s great to see how our optics kernel helps our customers to build innovative, state-of-the-art solutions at the forefront of ultra-precision machining” says Lothar Glasmacher, Head of Business Additive and Process Technology at ModuleWorks.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided design ( CAD)

computer-aided design ( CAD)

Product-design functions performed with the help of computers and special software.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.

- toolpath( cutter path)

toolpath( cutter path)

2-D or 3-D path generated by program code or a CAM system and followed by tool when machining a part.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.