ModuleWorks 2021.12 CAD/CAM Software Components

ModuleWorks 2021.12 CAD/CAM Software Components

This is the third ModuleWorks release of 2021 and contains new and enhanced features across the entire product range, including new multi-axis hole making cycles with independent feed rate control, a new morph pattern for laser aided manufacturing and a collision-free solution for robotics post processing.

ModuleWorks Releases 2021.12 Digital Manufacturing Software

ModuleWorks announces the release of its 2021.12 CAD/CAM software components for digital manufacturing. This is the third ModuleWorks release of 2021 and contains new and enhanced features across the entire product range, including new multi-axis hole making cycles with independent feed rate control, a new morph pattern for laser aided manufacturing and a collision-free solution for robotics post processing.

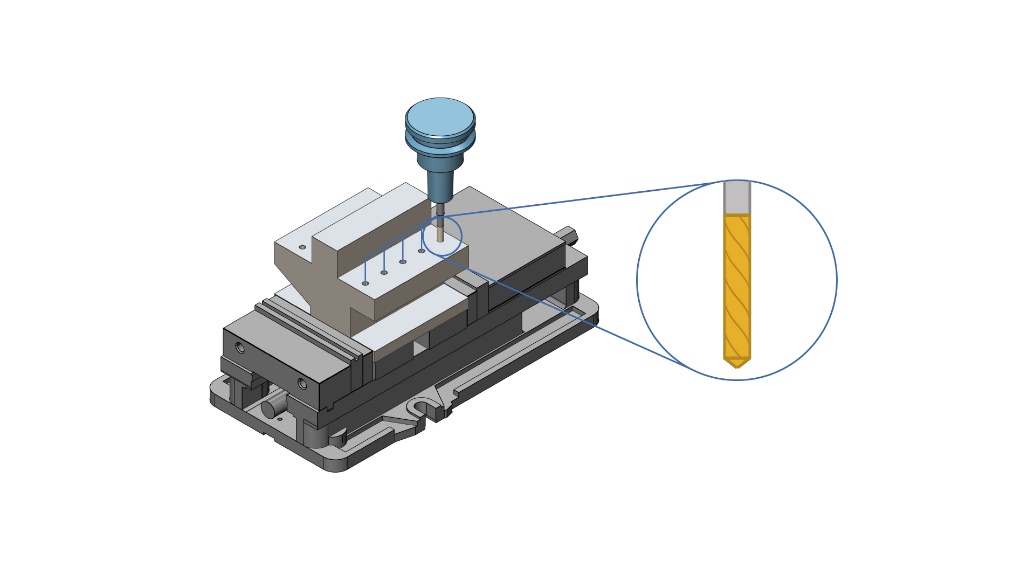

New hole making cycles for multi-axis machining

The new ModuleWorks hole making strategies provide flexible feed rate control for drilling, reaming and thread tapping with fast programming via a graphical user interface.

When drilling holes, operators can select a different feed rate for the break-through distance to reduce the amount of burr. This can also be used on non-flat holes to ensure a high-quality finish and longer tool life.

Reaming increases the precision of holes. With the new ModuleWorks hole making options, operators can select different approach and retract feed rates to ensure optimal machining conditions for reaming cycles.

The feed rates can also be independently adjusted for thread tapping. Selecting the right feed rate for retract motions reduces non-productive time and speeds up machining.

Morph pattern for laser aided manufacturing

The morph pattern can now be applied to laser aided manufacturing to create a morph toolpath between two leading curves or two guide meshes. The toolpath gradually interpolates between the two input objects and spreads evenly over the machining surface. This is especially useful when machining steep areas during mold making.

When used for Fused Deposition Modeling, the morph pattern enables operators to create a morph toolpath for non-uniform geometries.

Collision-free robotics post processing

This new feature uses the ModuleWorks collision checking algorithm to compute a collision-free solution for robotics post processing. When calculating the inverse kinematics for robots, the ModuleWorks MultiXPost processor detects collision pairs in the robot's kinematics and takes them into account when generating the posted toolpath.