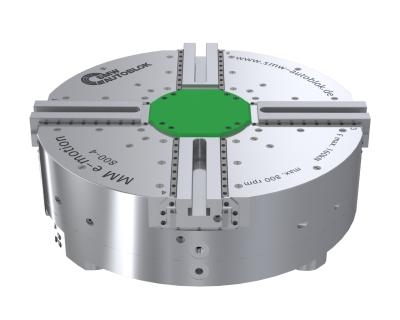

SMW Autoblok, a world leader in the design and manufacture of rotational chucks, stationary workholding, tooling and custom engineered solutions for the machine tool industry, introduces the fully sealed MM e-motion 4-jaw chuck providing contact-free adjustment of the gripping force without unclamping parts during every phase of the production process.

Each jaw of the MM e-motion is independently controlled and monitored by an individual electro-mechanical drive, which allows for many clamping functions including self-centering, compensating, and individual jaw movement all within one fully automated chuck.

Ideal for mill turn applications, horizontal and vertical lathes, the MM e-motion is optimum for heavy duty precision machining of easily deformed workpieces and provides an automatic center adjustment for any workpiece shape or configuration including round, square, rectangular, and irregular shapes in addition to workpieces with different wall thicknesses. The MM e-motion is also offered in a lightweight (LW) version that is ideal when mill turn load bearing capacity on the spindle is limited. The LW features the same functionality as the standard MM e-motion yet allows for higher workpiece weight and more usable Z stroke.

The chuck body and internal parts are case hardened for increased chuck life and highest rigidity, precision and durability. This specialty power chuck accepts inch serrated top jaws and is available in sizes from 500-1250 mm.

Ideal for Industry 4.0, permanent monitoring of the grip force and jaw positions can be stored and recalled for when the process needs to be repeated therefore, digital data is easily interchanged between different machines in the same production facility or at other facilities worldwide.

SMW Autoblok’s MM e-motion uses the newly developed F280 wireless inductive radial coupler system that transmits energy and data contact-free through an air gap of approximately 3 mm between rotating and stationary components. The IP67 rated inductive coupler system includes a stationary coupler and a movable mobile coupler. The stationary coupler is incorporated into the machine or into set-up station and the mobile coupler is incorporated on the pallet side. Power of up to 1500 watts can be transmitted between the stationary and mobile couplers and two CAN bus channels and two digital signals can be transmitted.

Contact Details

Related Glossary Terms

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- precision machining ( precision measurement)

precision machining ( precision measurement)

Machining and measuring to exacting standards. Four basic considerations are: dimensions, or geometrical characteristics such as lengths, angles and diameters of which the sizes are numerically specified; limits, or the maximum and minimum sizes permissible for a specified dimension; tolerances, or the total permissible variations in size; and allowances, or the prescribed differences in dimensions between mating parts.