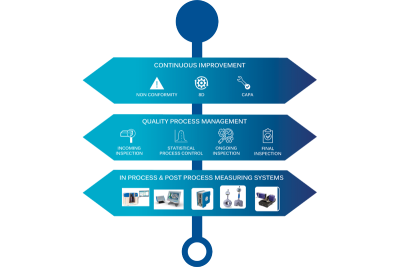

Marposs has announced MAINDO, its new Digital Platform that integrates Marposs monitoring, measuring, testing or other manufacturer device/solutions throughout the entire production process, combining quality and process into a holistic production monitoring view. Marposs modular software systems, comprised of brands such as Blulink, MG, Brankamp, Artis, S&K, enable a direct network connection between a production level system, a process monitoring system or a PLC terminal and the production control and quality management systems with higher-level company systems like ERP, PLM, MES, etc. The MAINDO platform offers improved production quality, reduced costs, traceability and remote data accessibility.

MAINDO embodies Industry 4.0 principles by integrating, sharing and enhancing data generated by Marposs systems focused on quality control, production processes and environmental conditions. Data that is typically stored in separate domains --- such as machine parameters, production process information, inspection results and continuous improvement process information -- are brought together to into a single view to provide information for failure detection and prediction. Root cause analysis and domain know-how bring at-a-glance information to all stakeholders with customizable dashboards.

In addition, QuartaEVO, Marposs Quality Management Software, provides a structured business process, based on industry sector standards, to assure a secure and efficient quality assurance process for product prototyping, through serial production up to incoming and outgoing goods inspection. Quality and preventive actions to continuously improve product quality, processes, the overall company effectiveness.

The MAINDO platform provides instant access to the following:

- Device and process data updates

- Multi-level failure detection

- Root cause analysis and continuous improvement

- Device asset management

- Device and process data updates

- Global access to devices and process data to recognize malfunction, update software components, gather development specific data, recognize and predict level of service.

Contact Details

Related Glossary Terms

- quality assurance ( quality control)

quality assurance ( quality control)

Terms denoting a formal program for monitoring product quality. The denotations are the same, but QC typically connotes a more traditional postmachining inspection system, while QA implies a more comprehensive approach, with emphasis on “total quality,” broad quality principles, statistical process control and other statistical methods.

- quality assurance ( quality control)2

quality assurance ( quality control)

Terms denoting a formal program for monitoring product quality. The denotations are the same, but QC typically connotes a more traditional postmachining inspection system, while QA implies a more comprehensive approach, with emphasis on “total quality,” broad quality principles, statistical process control and other statistical methods.