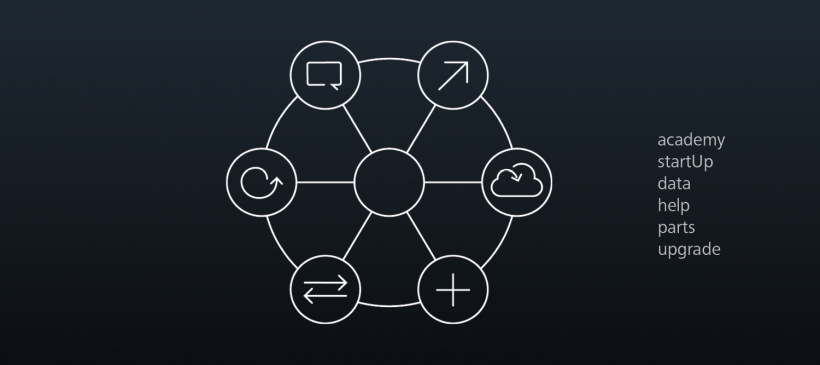

What would form the perfect service relationship for your investments in machine tools and production systems? Spare parts designed and engineered for your equipment? Commissioning and setup services? Training? All these and more are available from SW North America covering six modular areas in what the company calls Life Services.

The six categories cover:

- through lifeacademy, conducted on site at the customer’s facility or available through SW’s training centers in North America, Europe, and China;

- fast and productive startUp of your production system;

- monitoring, collecting, and analyzing machine data for predictive maintenance and for assuring a number of production efficiencies;

- 24/7 support and help online or in person;

- spare parts including assembled modules plus a strategy for planning when you need them; and

- upgrade assurance that your production evolves along with SW engineering and production advances.

Training through SW’s lifeacademy covers a customized combination of coursework and targeted individual consultation to achieve the most efficient operation, maintenance, and programming of SW equipment. Emphasizing hands-on instruction, worker understanding of SW systems continues appreciating throughout equipment life cycles, with high productivity as the initial benefit.

Machine commissioning services through startUp not only cover initial machine setup, but also an SW technician available for you on site for a defined period of time for advice and hands-on help. From installing custom fixtures to identifying and eliminating any squeaks, efficient setup leading to productive operation from the start is assured.

Collecting, monitoring, and compiling SW equipment data provides the numerous advantages of digitalization and the Fourth Industrial Revolution (Industry 4.0): better predictive maintenance, greatly reduced downtime, quickly simulating and achieving production advantages, and increased production efficiencies. Services include pilot project analysis, production process and material flow consulting; and modeling the digital factory for various simulation scenarios.

When it’s help you need, if your system is identifying a fault, SW service specialists make helping you the highest priority. Together with you they will find the best and fastest way to have your machine back in production, from online assistance to in-person service calls. Your operations staff can always rely on expert know-how from SW development and production departments.

Contact Details

Related Glossary Terms

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.