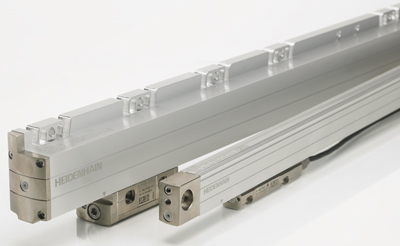

LC 195C and LC 495S Sealed Linear Encoders

LC 195C and LC 495S Sealed Linear Encoders

The new absolute LC 195S and LC 495S sealed linear encoders from HEIDENHAIN are now available for use on machines that need to be certified for functional safety.

The new absolute LC 195S and LC 495S sealed linear encoders from HEIDENHAIN are now available for use on machines that need to be certified for functional safety. The dual sealing lips on the LC 195S provides an extra layer of protection against contamination, and their extrusions ensure high vibration resistance, making these encoders extremely reliable and accurate.

These new encoders improve upon HEIDENHAIN's LC xx3 series, as the LC 195S/495S now focus on the requirements for purely-serial absolute systems for Siemens SINAMICS drive components. The series product introduction has opened with the safety-related purely serial EnDat 2.2 (up to 16 MHz) encoder version.

he Functional-safety (FS) encoder versions are available for the EnDat 2.2 interface and now DRIVE-CLiQ interface. This means that these encoders can be used as single-encoder systems in safety-related applications, such as in axes with a linear motor. In addition to safe processing of the position values, these encoders provide fault exclusions for the loosening of the mechanical coupling for various types of mounting.

As mentioned, the LC 195S features an optimized sealing design with two successive pairs of sealing lips. When compressed air flows into the scale housing, the air flows in between the sealing lips to prevent contamination of the DIADUR graduation which is responsible for the positioning accuracy. The resolution of the LC 195S and the LC 495S with an accuracy grade of 3µm is 1 nm.