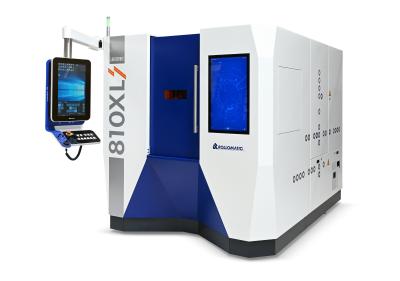

Rollomatic maintains its leadership position in the field of laser cutting ultra-hard materials by announcing the launch of another laser model within its line-up of 3 laser cutting machines.

The new model LaserSmart® 810XL with its innovative and powerful lase source has been designed for larger-diameter PCD tools (polycrystalline diamond) and other ultra-hard materials up to dia. 12”, a total length of 14” and a total load capacity of 33 lbs.

This machine is built on the success of the Rollomatic LaserSmart® series of machines and particularly addresses the profile cutting and ablation of diamond tooling in the larger diameter range as well as tools with a Monoblock adaptor. The ideal and typical application fields for this machine are the woodworking, automotive and aerospace industries.

These are some benefits which set this model 810XL apart from conventional laser cutting machines:

-

Achieves surface finishes as low as Ra 40 nanometers.

-

Patented axis configuration.

-

Produces crisper and sharper cutting edges compared to conventional laser machines.

-

30% faster feedrates compared to conventional laser machines.

-

Highly intuitive software based on the successful models 510 and 510 femto.

-

Software easily interprets 3D files and data entry. Communicates effortlessly with the operator and the machine systems.

-

Automatic blank detection.

-

Auto calculation of the tool structure & auto application of the dxf files to the blanks.

-

6 internal cameras assist the operator in quick setup and efficient production.

-

High repeatability and near-zero TIR in conjunction with in-process measuring.

-

Produces precise cylindrical margins on any tool size.

Contact Details

Related Glossary Terms

- polycrystalline diamond ( PCD)

polycrystalline diamond ( PCD)

Cutting tool material consisting of natural or synthetic diamond crystals bonded together under high pressure at elevated temperatures. PCD is available as a tip brazed to a carbide insert carrier. Used for machining nonferrous alloys and nonmetallic materials at high cutting speeds.

- total indicator runout ( TIR)

total indicator runout ( TIR)

Combined variations of all dimensions of a workpiece, measured with an indicator, determined by rotating the part 360°.