GF Machining Solutions presents an expanded range of laser texturing solutions at EMO Milano 2021, including the LASER P 400 Femto Flexipulse U and a virtual demonstration of the LASER S 2500 U.

The AgieCharmilles LASER P series provides easy, repeatable laser engraving texturing and structuring for small parts, such as watches, jewelry, cutting tools, small inserts and micromachined workpieces.

As with all of GF Machining Solutions’ LASER machines, the LASER P 400 series offers repeatable high performance, consistent accuracy and unvarying quality. Fully digitized texturing makes it easy to texture, mark, engrave and add functional surfaces to parts, molds and dies, even when dealing with complex 3D parts.

The modular concept of the AgieCharmilles LASER P 400 U Femto Flexipulse includes a patented dual-laser head that features both a fiber nanosecond laser and a femtosecond pulsed laser. This enables shops to texture and engrave a surface with a single machine with multiple setups, and extends the range of materials that the machines can process. In sum, it offers unparalleled flexibility with capabilities for roughing and finishing.

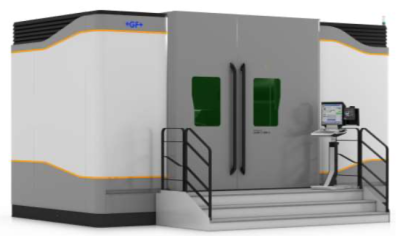

With a footprint of just 1229 mm x 2230 mm (48.4" x 87.8"), the LASER P 400 machines are easy to incorporate into a limited production environment. They accommodate workpieces of up to 600 mm x 399 mm x 249 mm (23.6" x 15.7" x 9.8").

The automation-ready LASER P 400 series enables unattended night and weekend operation. The machines easily partner with a System 3R pallet changer or other part handlers to boost efficiency and flexibility further.

The second machine displayed virtually at EMO Milano 2021 is the AgieCharmilles LASER S 2500 U, dedicated to the automotive industry. Designed to answer upcoming trends in e-mobility, this fast, accurate new machine within the S series makes textured surfaces possible, increasing product differentiation. The table can accommodate large size molds of up to 10 tons, for example for dashboards and door trims, the monobloc tri gantry design combined with thermo-stabilized areas of the machine ensure the highest graining quality.

Here again, fully digitized texturing makes it easy to texture, mark, engrave and add functional surfaces to parts, molds and dies. In addition, it replaces hazardous and even polluting processes with a sustainable solution. With the capabilities of this large, versatile machine, automotive OEMs can discover new ways to achieve the highest branding scores and stay ahead in this volatile and competitive market.