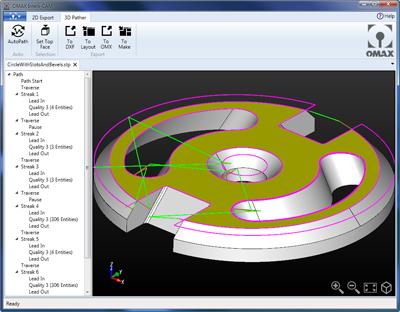

OMAX Corp. and Spatial Corp. have combined their technologies to create an easy-to-use 3D tool pathing solution. The new Intelli-CAM software tool for OMAX JetMachining Centers generates 3D tool paths from solid 3D models as well as quickly performs 3D to 2D file conversions. Intelli-CAM incorporates Spatial's 3D InterOp to import CAD files from a variety of 3D sources, including CATIA, SolidWorks, Solid Edge, Autodesk Inventor, Siemens NX, Pro/E, Creo and more.

Intelli-CAM then applies custom solutions from OMAX and Spatial such as the advanced AutoPath function or slice plane to convert the geometry into full 3D paths suitable for waterjet cutting.

"Helping OMAX expand the 3D capabilities of Intelli-CAM highlights the power of the Spatial component platform and the value our partnership with OMAX," explained Vivekan Iyengar, vice president of research and development for Spatial. "For Spatial, data reuse means delivering data in a manner that allows applications to more easily integrate into existing workflows with minimal disruption and high reliability. Reliability is important to OMAX. To their end user, any problem in the workflow has an associated cost and is typically seen as a problem in the application, not as a problem in the integrity of the incoming CAD model. 3D InterOp does the most to prevent the user from ever seeing those problems by automatically cleaning and repairing the CAD model during the import process."

According to Carl Olsen, lead software engineer for OMAX, Spatial's 3D InterOp technology allows OMAX to provide extremely robust and proven 3D file import capabilities to its JetMachining Center owners. "Our customers can now import practically any major 2D or 3D CAD drawing out there, which is especially beneficial to job shops because they often don't know the original CAD system for a file," he said. "Plus, they don't have to purchase expensive CAD software filter packages."

Contact Details

Related Glossary Terms

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- computer-aided design ( CAD)

computer-aided design ( CAD)

Product-design functions performed with the help of computers and special software.

- waterjet cutting

waterjet cutting

Fine, high-pressure (up to 50,000 psi or greater), high-velocity jet of water directed by a small nozzle to cut material. Velocity of the stream can exceed twice the speed of sound. Nozzle opening ranges from between 0.004" to 0.016" (0.l0mm to 0.41mm), producing a very narrow kerf. See AWJ, abrasive waterjet.