Industrial Robotic Calibration & ISO-based Performance Test Solution

Industrial Robotic Calibration & ISO-based Performance Test Solution

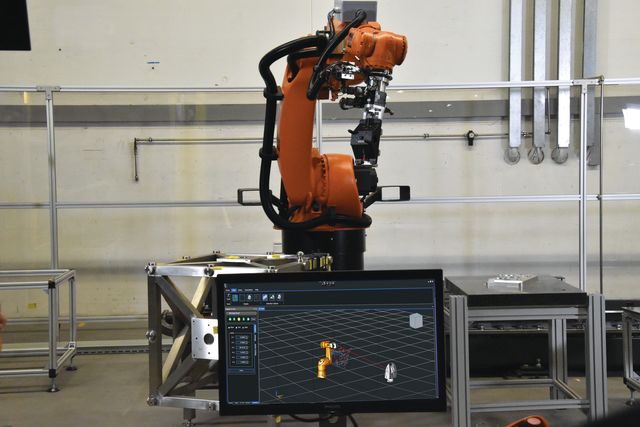

Hexagon Manufacturing Intelligence announced its new solution for the calibration and performance testing of industrial robot systems. The RoboDyn software package, created in collaboration with the developers of SpatialAnalyzer, works in conjunction with a Leica Absolute Tracker to allow for the direct calculation of robot characteristics such as base and tool alignments and full DH parameters.

Hexagon Manufacturing Intelligence announced its new solution for the calibration and performance testing of industrial robot systems. The RoboDyn software package, created in collaboration with the developers of SpatialAnalyzer, works in conjunction with a Leica Absolute Tracker to allow for the direct calculation of robot characteristics such as base and tool alignments and full DH parameters. Positioning accuracies are stated to the rigorous ISO 9283 certification standard.

The software's calibration module provides a fast and intuitive process for aligning the robot with the laser tracker and then calibrating the robot's kinematic configuration to improve absolute positioning accuracy. An ISO test module allows for performance testing according to the ISO 9283 standard, while a simulation module can be used to model and analyse line-of-sight issues and perform offline path creation prior to connection to the physical system.

"RoboDyn is a great piece of software that solves several of the key challenges of industrial robotics within a single easy-to-use package," said Markus Steiner, product manager software for Hexagon Manufacturing Intelligence's laser tracker systems. "Innovations like this show just how versatile our Leica Absolute Tracker technology is, and how high the returns can be when that technology is applied within the area of industrial automation."

Santiago Droll, project manager for RoboDyn, added, "For as long as I can remember it has always been difficult for people to live in both worlds–the metrology world and the robotic world. RoboDyn is the ideal tool to deal with this issue. It unifies the two and takes away the need to be an expert in both domains, by providing a neat and straightforward way to align, calibrate and evaluate the performance of any robot."