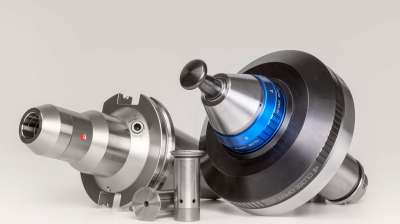

MAPAL offers hydraulic chucks specially for tool grinding machines, the HydroChuck Grind-A and the HydroChuck Grind-M. The advantages of MAPAL’s hydraulic expansion technology can thus now also be used for tool grinding. Both chucks ensure high-precision clamping and reproducible dimensional accuracy during grinding. They are designed for the shank tolerance h6 and score with their low wear and the associated high cost-effectiveness.

In addition to its high radial runout accuracy, the HydroChuck Grind-A with automatic workpiece clamping is characterised in particular by its energy-efficient function. The workpiece is clamped by means of a cup spring pack. The hydraulics of the machine are only required for releasing the workpiece. The hydraulic chuck is set and adjusted with μ-precision using two dial gauges in just a few minutes.

Wobble can be compensated, resulting in maximum workpiece precision. In addition, a uniform material removal and high surface finish quality can be assured. During the design, attention was paid to minimum tool restriction and hence the best possible grinding wheel runout. The new chuck offers not only reduced wear of the grinding wheel but also very close geometries, a constant quality and form/dimensional accuracy of the workpiece. The hydraulic expansion unit can be changed separately, the chucks can be completely overhauled.

In addition to the HydroChuck Grind-A, MAPAL also offers the new HydroChuck Grind-M for manual workpiece clamping. The tool to be ground is clamped here manually using a hexagon head screw. This chuck also allows the

benefits of the hydraulic expansion technology to be used for tool grinding.

Contact Details

Related Glossary Terms

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- grinding wheel

grinding wheel

Wheel formed from abrasive material mixed in a suitable matrix. Takes a variety of shapes but falls into two basic categories: one that cuts on its periphery, as in reciprocating grinding, and one that cuts on its side or face, as in tool and cutter grinding.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.