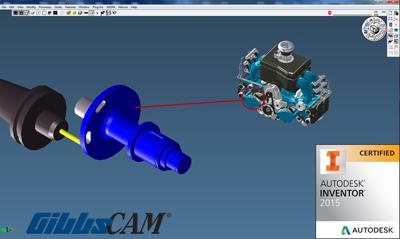

Gibbs and Associates announced that GibbsCAM has been certified for Autodesk Inventor 2015 3D mechanical design software under the Autodesk Certified Apps Program, marking the fourteenth consecutive year that GibbsCAM has been certified under the program. Digital prototyping with Autodesk Inventor software helps manufacturers to digitally design, visualize and simulate how a product will work under real world conditions before it is built. GibbsCAM directly opens Autodesk Inventor part models, allowing CNC programmers and machinists to easily and readily program machine tools from the models, extending cost reduction and efficiency through the programming and machining processes. Certification demonstrates that the product is of high quality and up to date, and that it provides the highest level of interoperability with Autodesk Inventor software.

"We are gratified for our continuing partnership with Autodesk and for Autodesk's recognition of GibbsCAM interoperability with Autodesk Inventor," said Robb Weinstein, Senior Vice President of Sales and Strategic Planning of Gibbs and Associates. "Our commitment to joint customers around the world remains unchanged, despite changing marketplace dynamics, as we continue to optimize the CNC-programming power and flexibility GibbsCAM provides."

"We are very pleased to have Gibbs and Associates affirm their continuing dedication to interoperability with Autodesk Inventor through Inventor certification for GibbsCAM," said Carl White, Senior Director, Manufacturing Engineering, Autodesk. "Having companies like Gibbs and Associates as partners is highly beneficial to our manufacturing customers."

GibbsCAM offers seamless integration with Autodesk Inventor, by directly reading Autodesk Inventor IPT (part model) files, preserving all color information, CAD and hole features and attributes assigned within Inventor to provide continuity in recognizing and communicating part and feature attributes. Alternatively, with the GibbsCAM Autodesk Inventor Add-in, the Inventor user can transfer files directly into GibbsCAM with the "Transfer to GibbsCAM" menu option of Inventor software running on the same workstation. Once machining processes are defined in GibbsCAM, they are automatically updated when the Inventor model is revised.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided design ( CAD)

computer-aided design ( CAD)

Product-design functions performed with the help of computers and special software.

- inches per tooth ( ipt)

inches per tooth ( ipt)

Linear distance traveled by the cutter during the engagement of one tooth. Although the milling cutter is a multi-edge tool, it is the capacity of each individual cutting edge that sets the limit of the tool, defined as: ipt = ipm/number of effective teeth 5 rpm or ipt = ipr/number of effective teeth. Sometimes referred to as the chip load.