DP Technology, maker of the popular ESPRIT CAM software, now offers a suite of probing cycles. Probing, which uses a sensitive touch probe to assess the dimensions of the workpiece, is an important part of any machining process. Although probing support is not new for ESPRIT, the new features of the option make it a valuable addition for manufacturing professionals. These features include:

● Offline inspection programming, which offers users the benefits of virtual stimulation for program verification and collision detection

● Hassle-free post processing and full control over each probing routine

- Compatibility with more CNC machines and probe manufacturers

These new capabilities join the probing cycle’s existing features, such as:

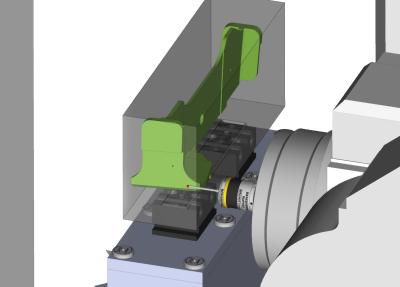

● Misload detection, which confirms correct part loading and reduces the risk of damage

● On-machine inspection, which generates consistent measurements and eliminates manual measuring errors

- Dynamic tool offsets, which automatically adapt the program considering tool wear

Using the combination of ESPRIT probing and CNC machines outfitted with touch probes, shops will enjoy increased throughput on existing equipment while reducing operator intervention. This benefit comes along with increases in part consistency and quality.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.