For centuries, the manufacturing industry has relied on subtractive machining. But over the last two decades, additive manufacturing—commonly known as 3D printing—has become a more widely used manufacturing process.

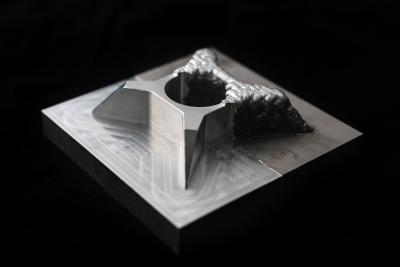

As one of the main additive manufacturing processes, directed energy deposition (DED) uses a focused energy source, such as a laser or electron beam, to melt the material. The ability to control the grain structure of a part makes DED a good solution for the repair of functional metal parts. For example, DED is often applied to rebuild large, expensive, and high-wear components for aerospace, energy, or marine industries, such as turbine blades, drill heads, or propellers. DED is also one of the few metal 3D printing technologies suitable for integration into CNC machines to create a hybrid manufacturing solution. By mounting a deposition nozzle on a multi-axis machining system, highly complex metal parts can be produced faster and with increased flexibility.

To satisfy this growing market demand, DP Technology is working closely with some of the world’s leading machine manufacturers to validate their brand-new additive cycles.

The DP Technology teams are proud to announce the very first commercial version of ESPRIT that includes additive direct energy deposition (DED) cycles. ESPRIT’s additive capabilities are the product of the team’s more than 35 years of experience in toolpath generations, and they include the same intuitive user interface that users expect from the software. The product release includes 3-axis, 4-axis, and 5-axis DED support. Combined with the subtractive processes and embedded into a single software, DP Technology brings a full spectrum of support to hybrid manufacturing.

ESPRIT’s additive DED cycles include additive simulation and verification, as well as global support from ESPRIT’s technical teams.

DP Technology validated their post processor through collaboration with major machine manufacturers and educational institutions. “For more than a decade, we’ve been working on additive manufacturing, including research on DED toolpath trajectories and AM thermal simulation. ESPRIT’s additive DED solution is the result of the close collaboration between DP Technology, the industry’s most trusted CAM solution provider, and Grenoble University, the world’s leading research institution on additive DED technology,” says Frederic Vignat, head of the additive department at Grenoble University in France.

The new additive cycle offers users a full-spectrum additive solution, from CAD file to finished part.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- computer-aided design ( CAD)

computer-aided design ( CAD)

Product-design functions performed with the help of computers and special software.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- toolpath( cutter path)

toolpath( cutter path)

2-D or 3-D path generated by program code or a CAM system and followed by tool when machining a part.