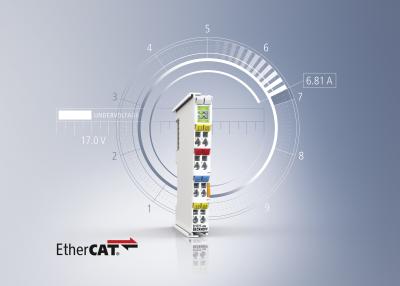

Beckhoff announced the new EL922x EtherCAT Terminal series, which directly integrates electronic overcurrent protection to safeguard 24 V DC system components in the EtherCAT I/O system. In comparison with currently available protection devices, costs and space requirements in control cabinets can be reduced without having to use conventional, inflexible stand-alone systems. With an extended range of settings and process data options, the 12 mm wide EL922x EtherCAT Terminals meet the most diverse requirements and enable transparent system monitoring.

The EL922x Terminal series for overcurrent protection is designed for 24 V DC operation and includes 19 different EtherCAT Terminals. There are 1- and 2-channel versions for various current loads up to a maximum of 10 A. The wide range of terminals includes:

- EL9221 and EL9222 Terminals with standard functionality such as rated current, which can be parameterized not only using TwinCAT System Manager software, but also conveniently with an LED button.

- EL9227-xxxx Terminals with extended functionality that can be parameterized in the TwinCAT System Manager, such as the selection of a characteristic curve, preliminary warning threshold, undervoltage signal, feedback cut-off, event logging and a password-protected software seal.

System-integrated overcurrent protection offers numerous practical benefits for users. Wiring effort is reduced since the feed into adjacent I/O terminals is achieved automatically by simply plugging in the terminal. In addition, control cabinets benefit from space and cost savings because additional coupling hardware and other digital I/O or power feeding products are no longer required.

Furthermore, numerous types of process data can be accessed via EtherCAT, for example utilization rate, load current, input/output current, undervoltage/overvoltage and feedback. This enables transparent system monitoring, minimized downtime, simplified troubleshooting and a comprehensive overview of plant history.

Contact Details

Related Glossary Terms

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.