With contactless inductive coupler systems, SMW-Electronics now offers the technology to transmit energy and data, contact-free, between stationary and moving components via an air gap. SMW-Electronics new full product range includes standard couplers as well as couplers for complex customer-specific designs.

Standard couplers are axial couplers with threaded fasteners commonly used in sensor technology. With their method of fixing these are easy to install and are quickly integrated, thanks to their plug & play functionality. The built-in LED display notifies the user of the system's status at all times. Radial couplers for rotary applications are available with diameters of up to 280 mm and large internal diameters. An inductive coupler system consists of a stationary coupler and a movable mobile coupler.

By using such couplers in a system, power can be supplied to sensors, actuators or control components and at the same time, any necessary data signals can be transmitted bidirectionally in analog or digital form. Transparent coupling of entire fieldbuses such as CAN or Profibus is also possible. Of particular note is the ability to transfer up to 1500 W of power at high bandwidths for operating actuators. Inductive transmission technology is completely wear- and maintenance-free and replaces traditional transmission methods using cables, contacts or slip rings. In automation applications especially, cables and contacts are subject to very high wear and tear and this can, for example, lead to machine downtime due to broken cables. Inductive coupler systems are protected to IP67 and can be used in harsh, demanding environmental conditions. In addition, they are also vibration-resistant.

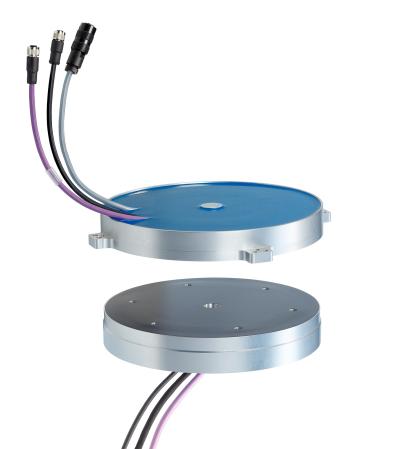

SMW's newly developed F280 inductive radial coupler transmits energy and data contact-free via an air gap of approx. 3 mm between its stationary and moving components. The inductive coupler system consists of a stationary coupler and a movable mobile coupler. The stationary coupler can, for example be incorporated into the machine or into set-up stations and the mobile coupler is incorporated on the pallet side. Power of up to 1500 watts can be transmitted between the stationary and mobile couplers. In addition, two CAN bus channels and two digital signals can be transmitted. Because it can transmit so much power, the F280 inductive coupler enables mechatronic clamping devices to be used on machine tools.

SMW-Electronics also uses the couplers in its newly launched "e-motion" product line. The mechatronic clamping devices in the e-motion line include the MM electromechanical e-motion 4-jaw chuck with individually driven jaws, and the RT electromechanical e-motion tombstone with drive interfaces for up to eight universally configurable clamping devices that can be individually controlled. The F280 inductive coupler system is standardized for all e-motion products This enables all e-motion products to be rapidly changed on the machine tool. The contactless coupler system makes it possible to monitor and adjust every clamping device at all times during the production process. This brings an enormous increase in flexibility, quality and operational safety.

Contact Details

Related Glossary Terms

- chuck

chuck

Workholding device that affixes to a mill, lathe or drill-press spindle. It holds a tool or workpiece by one end, allowing it to be rotated. May also be fitted to the machine table to hold a workpiece. Two or more adjustable jaws actually hold the tool or part. May be actuated manually, pneumatically, hydraulically or electrically. See collet.