BIG KAISER introduces the Base Master Red, a high-precision touch sensor that rapidly determines workpiece offsets and tool lengths, and the Base Master Mini, a thin, compact tool offset sensor.

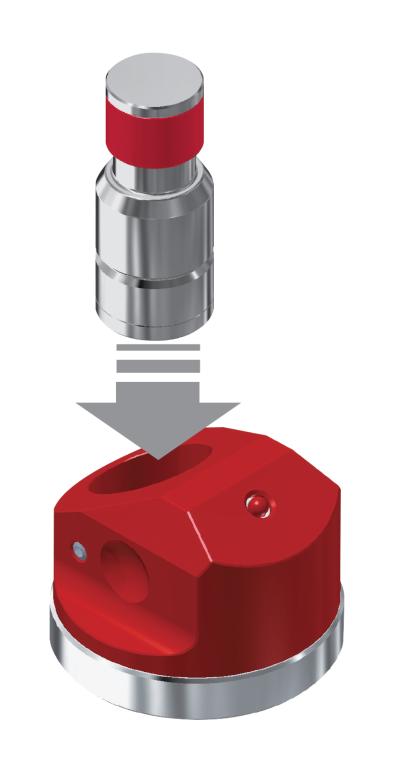

Part of BIG KAISER's popular Base Master family, the Base Master Red (pictured) can be used with all types of machines and materials, including non-conductive cutting tools, workpieces and machine tools. The Base Master Red allows the operator to quickly touch off a tool with zero risk of damage or breakage, saving time and money.

Additionally, since the body set and measuring sensor are independent of each other, maintenance becomes very easy, comprising of simply replacing the measuring sensor. This allows users to avoid expensive repair costs and long delivery times.

The Base Master Red has a tight repeatability of only ±0.001mm. For maximum flexibility in real-world conditions, it has a solid magnetic base that mounts vertically, horizontally, or at any angle.

The Base Master Mini’s compact design makes it very fast and easy to use while providing extremely accurate results. The main feature of this sensor is the very slim height of only 10mm (.397"). This is ideal for small lathes where working space is very limited.

For rapid reference point detection, it is fitted with a bright green LED light and is compatible with all workpieces. With a battery life of 10 hours of continuous use, the sensor will not disappoint when most needed.