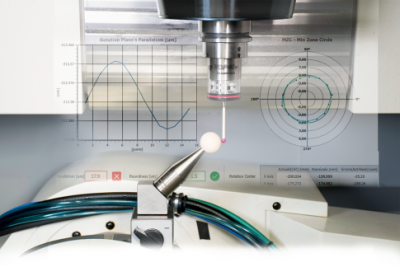

Marposs introduces AxiCheck—a software package with a graphic interface that analyzes data collected with Marposs probes, processing it in a graphic format to easily determine the operating state of the machine. AxiCheck helps increase production capacity by quickly and accurately inspecting the state of health of the machine, allowing users to identify and correct errors that may impact the workpiece, as well as planning maintenance operations in advance. This reduces the number of reject parts, particularly when dealing with single batches of expensive part production.

Parallelism of the axis of rotation and accuracy of its center are fundamental characteristics for the proper functioning of a machine tool with rotary axes. AxiCheck takes measurement to determine the reference values on a calibration sphere, mounted on the machine table to determine the machine’s operating health. Designed for use on 3- and 5-axes machines, AxiCheck is capable of monitoring and optimizing the performance of the rotating axes (5 Ax) while detecting any deterioration in the machine’s linear axes (3 Ax) in real time. It also features warning and alarm messages to alert the user if the measurement is out of tolerance.

Advantages of AxiCheck can be summarized as follows:

- Graphical machine error detection

- Increase in production capacity

- Reduction of scrap and rework

- Visualization of error evolution with alarm threshold for maintenance planning

- Detection of parallelism errors of the rotary axes and centers of rotation of the machine

Contact Details

Related Glossary Terms

- calibration

calibration

Checking measuring instruments and devices against a master set to ensure that, over time, they have remained dimensionally stable and nominally accurate.

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.