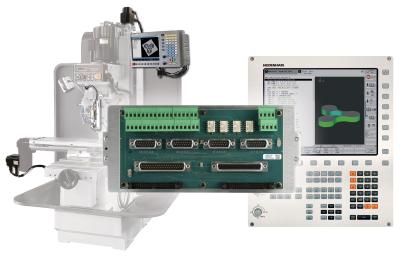

A new ACU-RITE adapter to enable a bridge from an ACU-RITE CNC control to a HEIDENHAIN control on the same machine was introduced in September at the IMTS show in Chicago (Sept. 12-17). This new product bridges the gap to bring an ACU-RITE control user to the next step, an entry-level HEIDENHAIN TNC 320 control, all on the same machine tool.

This new system from HEIDENHAIN’s ACU-RITE brand will be especially useful for shop owners who want to easily upgrade their machine already equipped with an ACU-RITE MILLPWR control to the next-step HEIDENHAIN TNC 320 or to switch between both controls such as in teaching environments at trade schools and in machine shops.

The PCBA was developed to allow ACU-RITE controls users to define and order a TNC 320 for small machine tool applications (i.e., VMC with tool changer) as a simple upgrade. This new system includes the PCBA adapter, a TNC 320 control and a complete AC package (motors, drives and electrical cabinet).

Two options will be available:

- Kit Style: For a user who has an ACU-RITE bed mill kit installed on a machine and they want to add the flexibility of the HEIDENHAIN TNC 320, the interface PCBA adapter can accommodate the functionality by using the backend ACU-RITE components. The use could be educational where most instructing is done on the ACU-RITE MILLPWR or TURNPWR control but there is a need to show advance functionality of the TNC 320. This allows users to become experienced with HEIDENHAIN entry-level controls.

- OEI: This is the console-only option that a builder can integrate into the machine, using ACU-RITE’s backend components. This can be used for CNC ready machines that have older controls and the end user wants to upgrade.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.