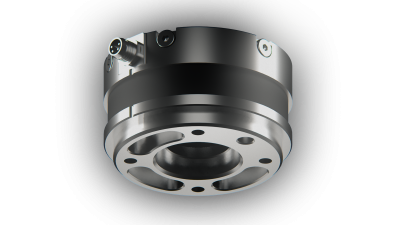

Easy-to-install, light-weight and robust, the OptoForce 6-axis sensors create a sense of touch for robots required to perform high-precision work, such as polishing, box insertion and other finer assembly tasks. Currently compatible with robots from Universal Robots and KUKA, and soon with ABB and Yaskawa, OptoForce sensors automate these tasks, increasing efficiency, speeding project development and decreasing overall production costs.

“With robots working more closely with humans, they need to accurately and precisely sense their surroundings and accomplish many tasks requiring the dexterity and sensitivity of the human hand,” said Ákos Dömötör, CEO, OptoForce. “Equipped with OptoForce high-precision sensors, these robots can now feel if they are placing an object in the right place or need to adjust it, and can automatically correct course. This speeds the production process and ultimately decreases costs, an ideal scenario for many U.S. manufacturers that have long offshored production due to high labor costs and the traditionally high cost of automation.”

OptoForce founders, then university students, worked together on a walking robot, where they faced constant issues with the weight, rigidity and cost of then available multi-axis force sensors. To address the many challenges, they developed a prototype of the current sensors that used infrared light to detect deformations of the silicone sensor structure. This new approach reportedly forms the basis of the OptoForce solution and guarantees precise measurements even up to 200 percent overload.

Contact Details

Related Glossary Terms

- polishing

polishing

Abrasive process that improves surface finish and blends contours. Abrasive particles attached to a flexible backing abrade the workpiece.