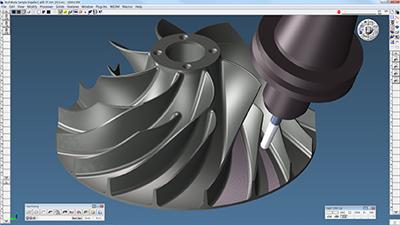

GibbsCAM announced availability of two new options for GibbsCAM specifically developed to simplify the 5-axis programming required to make turbomachinery parts. The new options have user interfaces that are optimized for fast selection of geometry and toolpath parameters to program machining of impellers, blisks (bladed disks) and blings (bladed rings). These bladed parts, which are used in compressing gas and liquids, or transporting them under pressurized flow, are common components in the aerospace, automotive and power generation industries.

Each of the two new software options targets different levels of specialization and part complexity in bladed-part manufacturing. While 5-Axis MultiBlade Level 1 is designed for parts of simpler to moderate complexity, 5-Axis MultiBlade Level 2 increases the selectable toolpath options to accommodate the most complex bladed parts, which may have multiple smaller blades (known as splitters and sub-splitters) between the main blades. The GibbsCAM 5-Axis MultiBlade options operate within the GibbsCAM 5-Axis software, accommodate both 5-axis machining centers and multi-task machines, and are available immediately.

When added to GibbsCAM 5-Axis, MultiBlade Level 1 simplifies programming and machining of blisks, blings and impellers having single splitters or no splitters. Toolpath strategies include 5-axis simultaneous roughing, hub finishing, and blade and splitter finishing, with automatic gouge checking on all toolpaths. The interface includes options for leading- and trailing-edge extension and control, plus intelligent controls for rotating toolpaths around the part.

Roughing between blades with splitter support

Blade, splitter and hub finishing

Leading- and trailing-edge extension and control

Tool axis tilt controls

Toolpath axis rotations

Automatic axis detection

Automatic and user definable links and clearances

When added to Level 1, MultiBlade Level 2 provides incremental capabilities to simplify programming and machining of parts that have multiple splitters and/or sub-splitters. It adds a fillet machining strategy and provides additional control for all toolpath strategies.

Blade fillet finishing

Tool axis smoothing

Splitter smoothing

Multiple splitter support

More control for tilt, leading & trailing edges, and all toolpath strategies

Toolpath segment sorting

Stock definition for rest machining

In addition to simplifying and speeding up the programming process, the GibbsCAM 5-Axis MultiBlade options generate cleaner, more efficient toolpaths for faster machining, better surface finish, and higher quality parts.

Contact Details

Related Glossary Terms

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- fillet

fillet

Rounded corner or arc that blends together two intersecting curves or lines. In three dimensions, a fillet surface is a transition surface that blends together two surfaces.

- finishing tool

finishing tool

Tool, belt, wheel or other cutting implement that completes the final, precision machining step/cut on a workpiece. Often takes the form of a grinding, honing, lapping or polishing tool. See roughing cutter.

- toolpath( cutter path)

toolpath( cutter path)

2-D or 3-D path generated by program code or a CAM system and followed by tool when machining a part.