OnRobot continues to drive innovation with the release of the compact, large-stroke 3FG15 three-finger gripper. The 3FG15 makes previously hard-to-automate precision handling of cylindrical parts easy to program and deploy, and provides flexibility for a wide range of part sizes.

“Our new 3FG15 three-finger gripper was developed as a response to existing pneumatic three-finger grippers that are bulkier and less flexible,” said CEO of OnRobot, Enrico Krog Iversen. “We have long defined the market for electric parallel grippers with the RG2 and RG6 series, and we look forward to addressing new market segments and applications with a new three-finger gripper that allows users to deploy applications faster even with highly accurate, fixed positioning.”

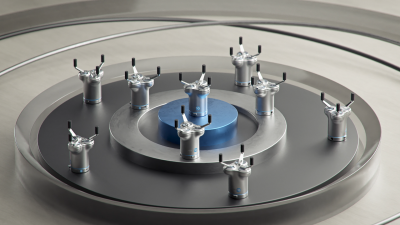

The 3FG15 gripper has a maximum stroke of 150 mm that can easily handle multiple processes. The innovative three-finger design with a 15 kg (33 lb) payload provides a strong, stable grip for both form fit (internal) or friction fit (external) gripping, adding flexibility to any implementation.

The gripper’s design, specifically developed for machine-tending tasks, automatically centers workpieces, resulting in a strong, stable grip and precise placement in machine chucks. With a gripping force from 10 N to 240 N, the 3FG15 competes with much less flexible finger grippers.

The gripper is also suitable for packaging and palletizing applications, and is seamlessly compatible with any major collaborative or light industrial robot arm through OnRobot’s new award-winning One System Solution, the platform that provides a unified mechanical and electrical interface between the robot arms and any OnRobot EoAT.

Contact Details

Related Glossary Terms

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- industrial robot

industrial robot

Robot designed for industrial use. Primarily used as a material-handling device but also used for changing tools, assembling parts, and manipulating special tools and measuring devices. Depending on design, an industrial robot can be programmed to perform a task by means of a controller, or it can be “walked” through the required movements by utilizing a digitizing system that translates movements into commands that the robot can be “taught.” See robot; teaching pendant.

- parallel

parallel

Strip or block of precision-ground stock used to elevate a workpiece, while keeping it parallel to the worktable, to prevent cutter/table contact.

- payload ( workload)

payload ( workload)

Maximum load that the robot can handle safely.