ModuleWorks Releases 2022.04 Digital Manufacturing Software

ModuleWorks announces the release of its 2022.04 CAD/CAM software components for digital manufacturing. This is the first major ModuleWorks release of 2022 and contains new and enhanced features across the entire product range, including the new blisk module for multiblade machining, undercut machining with slot mills and stock pillar removal for adaptive roughing.

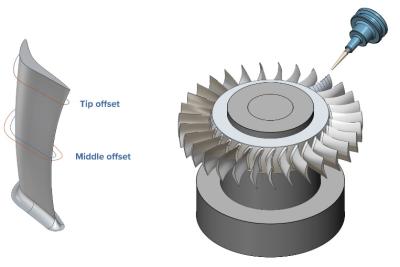

Blisk machining

The new blisk module provides parameters and settings for creating very smooth toolpaths for multiblade machining. Smooth toolpaths ensure consistent acceleration and, therefore, shorter cycle times.

Operators can adjust the variable offset at different locations on the blade to fine-tune the toolpath according to measurement results based on the coordinate measuring machine, without changing the complex 3D file.

Undercut machining with slot mills

This new option for the flatland cycle enables operators to machine flat undercut areas using slot milling tools.

Additional toolpath slices are generated on the flat regions of the undercut. The toolpath calculation algorithms use "out to in" ordering to remove the material gradually which enables the flatland cycle to machine parts with undercut features.

Stock pillar removal for adaptive roughing

The standard settings for adaptive roughing often leave a pillar at the center of the area being machined. This pillar can create adverse cutting conditions such as vibrations and localized heat generation.

The new stock-pillar-removal feature uses a spiral ramp motion to remove the pillar after the adaptive roughing cycle, thereby eliminating the vibrations and excessive heat to improve the cutting conditions and prolong the tool life.

Contact Details

Related Glossary Terms

- flat ( screw flat)

flat ( screw flat)

Flat surface machined into the shank of a cutting tool for enhanced holding of the tool.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- toolpath( cutter path)

toolpath( cutter path)

2-D or 3-D path generated by program code or a CAM system and followed by tool when machining a part.

- undercut

undercut

In numerical-control applications, a cut shorter than the programmed cut resulting after a command change in direction. Also a condition in generated gear teeth when any part of the fillet curve lies inside of a line drawn tangent to the working profile at its point of juncture with the fillet. Undercut may be deliberately introduced to facilitate finishing operations, as in preshaving.