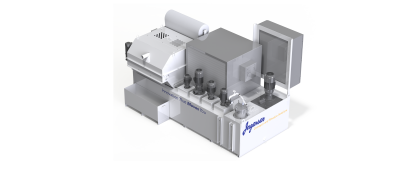

Jorgensen Conveyor and Filtration Solutions has introduced its new FlexFiltration line that also includes the company’s new Flex G Series of modular filtration systems. The new cost-effective systems feature pre-engineered modules that ensure fast, easy and flexible filtration system configurations for practically any filtering application.

FlexFiltration systems efficiently remove fine chips and grinding sludge to achieve coolant clarity down to 10 microns or less. They are especially well suited for challenging applications involving materials ranging from cast iron, steel and aluminum to composites and plastics.

Jorgensen has developed several pre-engineered base configurations that allow customers to quickly construct a FlexFiltration system specific to coolant-flow requirements. To further match the system to the intended application, the company offers a range of system tanks. These include standard or low-profile versions along with an optional stainless-steel tank that makes the new FlexFiltration system ideal for machine tool OEMs and end users alike. Other modular options that complete a system include high-pressure pumps, auxiliary pumps, tramp oil skimmers, coolant chillers, heat exchangers, liquid level sensors, temperature sensors and the ability to control/interface with existing pumps and other equipment.

“With the introduction of the FlexFiltration system, Jorgensen further expands its wide range of product offerings that positions us as a leading and single-source provider of conveyor and filtration systems for many different machine tool platforms and models,” said Karl Kleppek, Director of Sales and Marketing at Jorgensen. “Our goal is to always provide our customers with modern technologies developed to meet their specific filtering application needs.”

Included in the FlexFiltration introduction is Jorgensen’s Flex G Series systems featuring gravity media filters. The gravity media filtration option is the first one available in the FlexFiltration product line. Gravity filters are offered in 30, 60 and 90 gpm options and come standard with low media roll detection, no media alarm sensor and automatic roll advance. A variety of different disposable cloth medias are also available based on specific applications. Additional primary filtration options including bag filtration, cyclonic, and permanent media types will soon be offered.

Contact Details

Related Glossary Terms

- composites

composites

Materials composed of different elements, with one element normally embedded in another, held together by a compatible binder.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- tramp oil

tramp oil

Oil that is present in a metalworking fluid mix that is not from the product concentrate. The usual sources are machine tool lubrication system leaks.