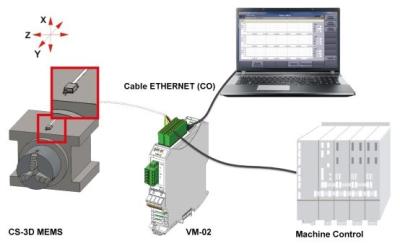

Marposs has announced the availability of its new standalone ARTIS VM-02, featuring a MEMS or 3-axis piezoelectric monitoring sensor that measures in-process machine tool acceleration values (g), helping to minimize damages after a dynamic crash. Part of the Genior Modular machine monitoring system family, the VM-02 is a low-cost, upgradeable solution with an ultrafast reaction time of <1 millisecond.

Through a 24V discrete IO communication protocol, the VM-02 can be easily integrated into any machine tool and CNC to mitigate machine damage, repair cost and downtime caused by dynamic collisions created by human mistakes (setup), errors in the NC program and machine operation.

Users load the VM-02 software onto a Windows-based computer, and the system then registers and documents exact identification of collision events as any unacceptable vibrations occur in the machine or tool. There are three different modes available for machine setting and acceleration measurement is provided in three axes and three windows. The transducer is designed for simple installation into the existing machine electrical cabinet. Three possible fast output alarms are available: hard stop, soft stop and warning limits can be set up for each axis.

As part of the Genior Modular tool and process monitoring systems, the VM-02 can be installed alone or by connecting the GEM CPU module to the VM-02 enabling mechanical vibrations (RMS or mm/s) to be measured during the cutting process in addition to the acceleration monitoring (g). With this configuration, additional measurement transducers can be added to monitor up to eight simultaneous process signals from the cutting such as force-strain, acoustic emission, true power, and torque, as well as FFT analysis. The Genior system is a comprehensive, fully automatic solution with multisensor and multiscreen visualization capability to effectively monitor the machine, spindles, axis and the tool to optimize the cutting process.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.