Industry News

06/07/2023

Zoller Inc. will host an automation-focused event called “Automate. Success.” The event Aug. 9 and 10 at the company’s Ann Arbor headquarters will offer a roadmap for how Zoller can digitize, automate and connect manufacturing processes to achieve greater efficiency and profitability.

06/06/2023

The Milwaukee Journal Sentinel recognizes Jorgensen Conveyor and Filtration Solutions as one of the best places to work in southeast Wisconsin.

06/05/2023

Touted as the Oscars of the cutting tool industry, #ANCATooloftheYear2023 is your chance to achieve global brand recognition as well as cash and other prizes.

06/02/2023

Sandvik Coromant is participating in Rota 2030, a federal government program designed to support and boost Brazil’s automotive sector.

05/30/2023

Additive manufacturing, or 3D printing, allows Seco Tools to create products that would otherwise be difficult or impossible to manufacture. The advantages include shorter lead times, improved tool life and increased sustainability.

05/26/2023

The tool manufacturing industry is embracing automation solutions at an unprecedented pace. This is a worldwide trend driven by several factors, and manufacturers need to be more flexible and responsive than ever before.

05/25/2023

The automotive industry has the largest number of robots working in factories around the world. Operational stock has hit a record of about 1 million units.

05/24/2023

United Grinding North America has launched a four-year apprenticeship program to provide aspiring individuals with an opportunity to earn a full scholarship from Sinclair College in Ohio while gaining invaluable hands-on experience.

05/23/2023

Emuge-Franken USA, Grob Systems Inc. and Concepts NREC are holding a complimentary Tech Day on June 7 from 10 a.m. to 1 p.m. Eastern time at the Emuge Technology Center in West Boylston, Massachusetts.

05/22/2023

Safety managers take on the hefty responsibility of keeping employees safe. Here are five tips to make the job easier.

05/19/2023

PVI Esskå in Landeryd, Sweden, manufactures chassis and body parts for trucks and uses hydraulic presses supplied and installed by AP&T. In summer 2022, AP&T upgraded and future-proofed one of the company’s press lines by rebuilding the control systems and installing new automation equipment. The investment reduced the line's cycle times by about 50% and increased production capacity by about 500 hours a year.

05/17/2023

“Accelerate Success” was the theme of this year’s Zoller Open House & Technology Days, which took place May 9-11 at Zoller Inc.’s headquarters in Ann Arbor, Michigan. Presented here are highlights from the May 10 agenda.

05/17/2023

Ceratizit’s executive director of technology and solutions, Mark Blosser, will bring future-oriented manufacturing solutions to Siemens Realize Live.

05/16/2023

An application specialist at Sandvik Coromant was honored for his years of volunteer efforts with the organization at its Shoptalk event.

05/15/2023

Aerospace and defense giant Leonardo — tasked by the Ministry of Defense to provide AgustaWestland AW101s for the British Royal Navy — found that its pre-existing main rotor blade restraint cradles were not living up to its standards. Additive manufacturing may have provided a solution.

05/12/2023

The Kentucky-built Mazak Ez series comes to Canada for the Western Manufacturing Technology Show in Edmonton from May 30 to June 1.

05/11/2023

Renishaw heads to Eastec to demonstrate its latest smart manufacturing innovation designed to optimize shop floor processes.

05/10/2023

GF Machining Solutions has moved its North American parts warehouse operations to an airport-adjacent location in Indianapolis, Indiana, to enhance responsiveness to customers and more quickly deliver parts orders.

05/09/2023

Mazak President Dan Janka has been named chairman of the board of The Association of Manufacturing Technology for the second time. He previously served as chairman in 2010.

05/08/2023

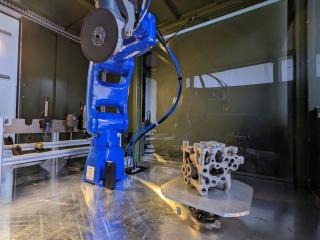

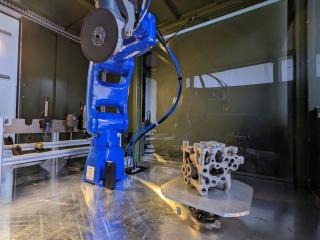

In metal additive manufacturing, post-processing of parts introduces time and financial constraints to the overall cost per part that can negate the benefits of AM altogether. How can you transition to automated support removal (and finishing) solutions, and what are the advantages of CNC systems?