Industry News

09/27/2019

Precision and efficiency have become the leading demands for manufacturing. Modern equipment is changing rapidly. Sturdier, harder materials are used, complex geometries with tight tolerances and fine surface finishes are required, and all that has to be done at a faster pace. This race toward product perfection involves using professional custom machining services for more and more industries and for a lot of different purposes.

09/24/2019

Blairsville, Pa. The National Center for Defense Manufacturing and Machining (NCDMM) proudly announces the opening of its newest office in Huntsville, Ala., to provide enhanced support to and greater engagement with the U.S. Army Combat Capabilities Development Command (CCDC) Aviation & Missile Center in Redstone Arsenal, Ala.

09/24/2019

Waconia, MN – Milltronics USA has named Hales Machine Tool, Inc. as its exclusive full service distributor for the state of Minnesota, North and South Dakota and Northwest Wisconsin, effective immediately.

08/26/2019

For any metalworker or engineer, from aspiring to advanced, the acclaimed Home Machinist series is the ultimate resource for everything you need to know!

08/20/2019

MxD announced a comprehensive workforce development program for cybersecurity in manufacturing, underwritten with a $1.25 million grant from the Siemens Foundation. The grant will fund the development and implementation of a highly skilled cybersecurity for manufacturing initiative as part of MxD’s workforce strategy known as MxD Learn.

08/14/2019

Eliminating unnecessary interruptions to production directly affects machining cycle times, costs to complete each part from start-to-finish and, by extension, the ability to bid competitively. Getting more hours a day out of your spindle is key to optimizing this equation.

07/18/2019

Schaumburg, IL – Kitagawa North-Tech, Inc., a brand in standard Chucks, engineered Chucks, Rotary Tables, Oil & Gas Chucks, large VTL Chucks, custom engineered Workholding and Steady Rests, has announced some changes to their sales organization, realigning their inside and outside sales teams for the company.

05/29/2019

Making chips means making money, so keeping the spindle turning is critical for a company's bottom line. Timothy Mooney, Midwest regional sales manager for Starrag USA, distributors of high-precision machine tools, said his customers strive for a 75 percent spindle engagement time "That is the only time that they are making money."

05/06/2019

Heinrich Georg Maschinenfabrik has received an order from Vítkovické Slévárny spol. s r.o. for the supply of a roll lathe, the third lathe so far supplied by GEORG to the Czech roll manufacturer. The new machine will be linked with one of the existing lathes. Thanks to this solution, only one operator will be needed to control both machines.

04/16/2019

In response to my Lead Angle column in the April 2019 issue about machining large parts and my attraction to vintage machine tools, I received the following email from Chuck Oloffson, a CAD detailer and former CNC and manual machinist.

04/03/2019

Elk Grove Village, IL – As of April 1, 2019, Niigata Machine Techno USA, Inc. will be the distributor of Niigata Injection Molding Machines.

03/11/2019

The following interview was conducted with Platinum Tooling’s President, Preben Hansen, at the company’s headquarters in Prospect Heights, Illinois. Hansen discusses the beginnings of Platinum Tooling, the transition period, changes, product lines and the future.

02/12/2019

One of the best parts of my job is visiting factories where metal parts are machined. In connection with the feature article I wrote for our April issue about machining large parts, I traveled to Romulus, Michigan, and visited Lincoln Park Boring Co.

02/06/2019

Waukegan, IL – LMT Tools is announcing that Rex Trammell has joined LMT Tools as the new Field Sales and Application Specialist covering the state of Tennessee along with the Gulf Coast area.

01/29/2019

Lightweight Innovations For Tomorrow, a national manufacturing innovation institute, announces its Heller FP 6000 5-axis machining center has been installed, and is ready for use, at its research and manufacturing facility in the Corktown neighborhood of Detroit. With the installation of this machine, Heller is assisting LIFT and its members to further develop next generation processes in lightweight metal manufacturing.

01/04/2019

Elk Grove Village, IL – Niigata Machine Techno USA, Inc., a specialist in horizontal machining centers, announces the appointment of Gregory Hobbs as its new Vice President of Sales and Marketing.

01/04/2019

SCHAUMBURG, IL (January 2019) – HEIDENHAIN is proud to announce Community College of Denver’s (CCD) Advanced Manufacturing Center (AMC) as the first HEIDENHAIN authorized training partner (ATP) focusing on its CNC controls in North America.

01/03/2019

FLORENCE, Ky., December 10, 2018 – With its sights set on further strengthening customer support, especially for those in the high-tech industries, Mazak Corporation has announced it will open a new Mazak San Francisco Technical Center.

12/20/2018

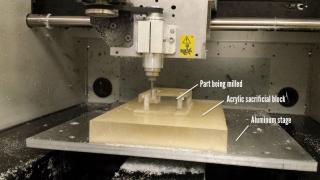

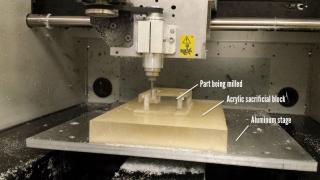

When machining for precision, there’s no such thing as planning too much. There are many important aspects to account for, from bit tapers to material burrs to caliper readings. Even what direction you attach your material to the stage can matter. Here are some quick tips to keep in mind as you plan your next machining project.

12/18/2018

New research by the Copper Development Association Inc., McLean, Virginia, shows that U.S. machine shops may be underutilizing the machinability of brass by as much as 85 percent in part-processing operations. The study says manufacturers can and should be machining the material at significantly higher speeds and feeds—often five to 20 times faster—to increase productivity and profitability.