Industry News

11/14/2021

Manufacturers can achieve 90% machine use reduction with power skiving.

10/28/2021

On its 80th anniversary, the KEO brand looks ahead to the future. The company's long-range strategy is to build upon the trust and reputation of the brand and to acquire diverse, complementary companies to drive overall growth.

10/21/2021

Tools today are far superior to those used in previous firearm production methods, which provides the opportunity to combine operations into a single cutting tool, eliminating the need for additional tooling in the machine shop.

10/19/2021

Machining titanium cost-effectively requires special attention to the distinctive features of this material – particularly for choosing the right tools.

10/05/2021

Predicting tool wear for process security and reduced waste in steel turning is a critical component of unmanned production.

09/28/2021

Advanced tool holders with precision coolant improve cost-efficiency in steel turning.

09/22/2021

The acquisition of Monster Tool Company adds significant depth to both the GWS general purpose and high-performance standard product portfolio.

09/19/2021

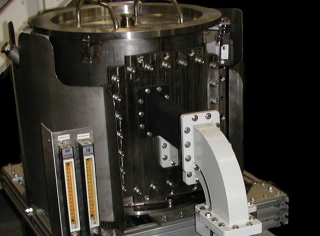

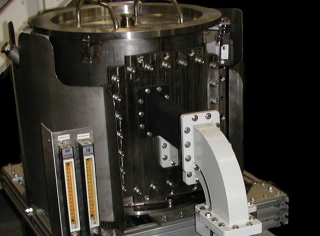

Transor's filtration system is used by Vollmer of America.

09/13/2021

GWS Tool Group has named Kent Carlsen an application specialist responsible for customers in Arizona, Colorado, New Mexico, Nevada, Utah and Wyoming.

09/07/2021

Branding for Gorilla Mill, a manufacturer of carbide drills, endmills and cutting tools, is simian-themed, aggressive and fun, and it comes with the tagline “Weapons of Mass Production.” The company has grown in employees, distributors and a diverse spread of customers. ANCA's CNC machines have played a large role in Gorilla Mill's progress.

08/27/2021

Fast, flexible custom tooling, easy access to tool data through cloud technology and automation are some of the technologies driving tool production processes, according to a recent discussion between two industry executives.

08/25/2021

Changing a three-axis machining process from a vertical machining center (VMC) to a horizontal machining center (HMC) offers many benefits.

08/23/2021

A tool manufacturer overcomes the challenges of excessive heat generation in the cutting zone.

08/13/2021

Supporting both the growth of U.S. manufacturing and the growth of the cutting tools market is ARCH Cutting Tools, with its expanded, all-American Patriot High Performance portfolio.

07/27/2021

To kick off this agreement, Transor will provide a filtration system to serve two saw blade grinding machines at Vollmer’s headquarters in Pittsburgh.

07/21/2021

Now in its fourth year, ANCA Tool of the Year has raised the profile of cutting tools and those companies who make them.

07/20/2021

The manufacturer of custom cutting tools joins more than 40 companies participating in the Thinc network.

07/19/2021

The Ceratizit Group acquisition of the remaining shares allows the Group to further expand its footprint and accelerate a growth strategy in the cutting tools market, specifically in high-end micro tools.

07/14/2021

GWS Tool Group in Tavares, Florida, finalized its third acquisition in 2021 and its first international acquisition with the purchase of Indexable Cutting Tools Inc.

07/09/2021

The global pandemic has impacted businesses around the world, but for Aiguisatek, a Canada-based sharpening service, the impact was compounded by stringent local regulation in the Quebec province that all but shut down manufacturing in the area. Automation technology solved these challenges.