Article from Shop Floor Automations, La Mesa, Calif.

If you are in charge of production on a manufacturing shop floor, there is no doubt that you have likely come across productivity issues. Nothing is perfect, and this includes your employees and your equipment.

When there is a decrease in productivity, some leaders may automatically assume that machinists are not doing their job since they are directly handling the machines. Before we jump to this conclusion, we need to ask if we are being fair to these skilled workers who are the backbone of the manufacturing industry.

According to a study shared by Harvard Business Review, “when leaders are fair to the members of their team, the team members display more citizenship behavior and are more productive, both individually and as a team.” With this in mind, here are three productivity problems and the tools you can use to combat each of them:

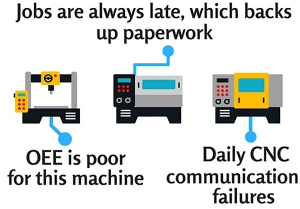

Problem: The operator is scrapping too many parts, or behind on the job. Most shops are also still loading from portable media like floppy disks or portable media. Answer: DNC Software can handle programs for thousands of machines and can help end CNC communication failures. Eliminate manual input of programs. Rest assured that Windows-based CNCs can connect to DNC software via a secure Ethernet connection, and that program transfers are encrypted, with Secure DNC.

Problem: The machines are always down, so the machinists must be using them in an unfit manner. Answer: Machine monitoring will help track machine trends to help improve OEE and productivity. It will help so that everyone on and off the shop floor has easy-to-understand data on machine behavior. Know when to do maintenance, when there are tooling issues, or when materials are needed. This data can also be turned into actionable items through data driven decision making.

Problem: Jobs are not on time, which creates unsatisfied customers, so the machinists are causing me to lose business and profitability. Answer: The first solution is to adopt graphical job scheduling into your routine. This will not only get rid of spreadsheets that have to manually be updated any time a job needs to be moved up or added, but it will also help to evaluate in real-time how moving one job will affect all others. The second solution is to look into product data management for your shop floor. This will help you go paperless, control revision and achieve compliance so you don’t have to worry about an audit.

As you can see by these three problems we highlighted, there is a solution so that you not only have data to make you feel better about your employees, but you will also be showing that you are a fair leader to your workforce. Have other shop floor issues that need solving? Feel free to ask us!

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- direct numerical control ( DNC)

direct numerical control ( DNC)

Method of transferring CNC code from the CAD/CAM system to the machine tool.