Article from Transparency Market Research

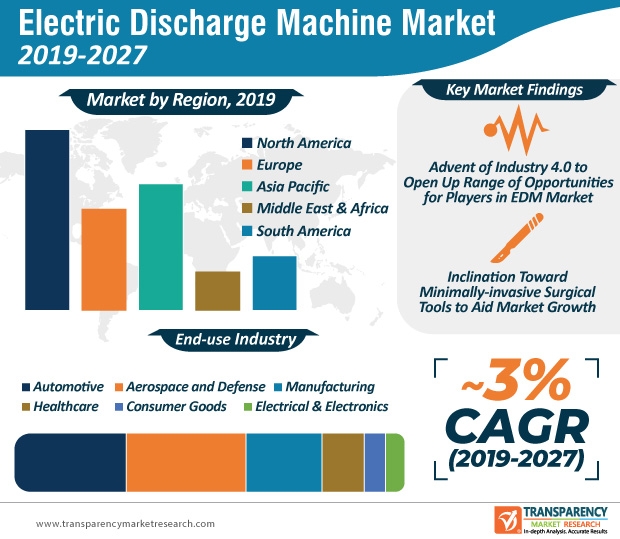

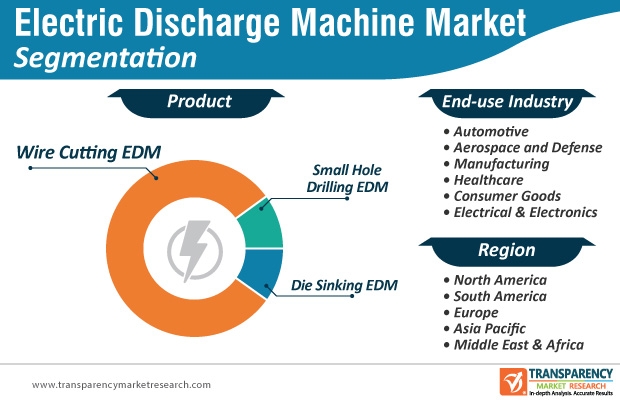

According to a new market report pertaining to the global electric discharge machine (EDM) market, that market is projected to reach a value of US$ 6.1 billion by 2027. The EDM market is expected to expand at a CAGR of ~6% from 2019 to 2027, in terms of volume. Growth of the EDM market can be attributed to increasing need for EDMs for the development of high-end machining designs in various industries. Asia Pacific is anticipated to lead the global electric discharge machine market, followed by North America during the forecast period.

Electric Discharge Machine Market to Witness Growth due to Future Dominance of Industry 4.0

Industry 4.0, widely known as smart factory, is considered the fourth era of industry that merges automation and computing, which can drive the manufacturing sector to move from machine tools to high-quality assurance tools. Industry 4.0 includes cyber-physical systems, factory simulation, autonomous robots, cloud computing, industrial internet of things, cognitive computing and additive manufacturing. Industry 4.0 can help simulate, design and take care of physical processes in manufacturing factories with EDMs for cost-effectiveness. It also combines an array of modern automation, intelligence, manufacturing technologies and data exchange.

Moreover, EDMs are preferred in the manufacturing of high-efficiency machines or equipment in manufacturing factories to save labor cost (as compared with conventional milling practices), while enhancing the quality of products, which can be used to meet the needs in Industry 4.0 across the world.

Electric Discharge Machine Market: Regional Outlook

In terms of region, the global electric discharge machine market has been segmented into North America, Europe, Asia Pacific, Middle East and Africa, and South America. Asia Pacific led the global EDM market, accounting for a substantial share in 2019, with China and India being the major markets in the region. The Asia Pacific EDM market is expected to grow at a CAGR of ~7%, in terms of volume, during the forecast period due to well-established builders of EDMs, such as Mitsubishi Electric Corp., Sodick Co. Ltd., FANUC Corp. and Sparkonix (India) Pvt. Ltd., in the region. The EDM market in Europe, Middle East and Africa, and South America is also expected to expand at a moderate rate during the forecast period.

The report provides in-depth segment analysis of the global EDM market, thereby providing valuable insights at macro as well as micro levels. Analysis of major countries, which hold growth opportunities or account for significant market share has also been included as part of the regional analysis for the electric discharge machine market.

Electric Discharge Machine Market: Competition Dynamics

The research study includes profiles of leading companies operating in the global electric discharge machine market. Key players profiled in the report include Mitsubishi Electric Corp., Sodick Co. Ltd., Makino Milling Machine Co. Ltd., Sparkonix (India) Pvt. Ltd., FANUC Corp., Georg Fischer AG, Excetek Technologies Co. Ltd, AccuteX Technologies Co. Ltd., Astro Machine Works Inc., Knuth Werkzeugmaschinen GmbH and Ona Electroerosion S.A.

Related Glossary Terms

- conventional milling ( up milling)

conventional milling ( up milling)

Cutter rotation is opposite that of the feed at the point of contact. Chips are cut at minimal thickness at the initial engagement of the cutter’s teeth with the workpiece and increase to a maximum thickness at the end of engagement. See climb milling.

- electrical-discharge machining ( EDM)

electrical-discharge machining ( EDM)

Process that vaporizes conductive materials by controlled application of pulsed electrical current that flows between a workpiece and electrode (tool) in a dielectric fluid. Permits machining shapes to tight accuracies without the internal stresses conventional machining often generates. Useful in diemaking.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.