A joint research project known as “Scaling Ultrafast Laser Productive Precision Processing Technology”, or ScULPT, was conceived to develop an efficient, powerful, ultra-short pulsed laser system with a tenfold increase in throughput on the machining of different types of glass and metals. Led by laser system manufacturer TRUMPF, a group of partners from science and industry is seeking to significant increase of the output power available from industrial grade ultra-short pulse lasers.

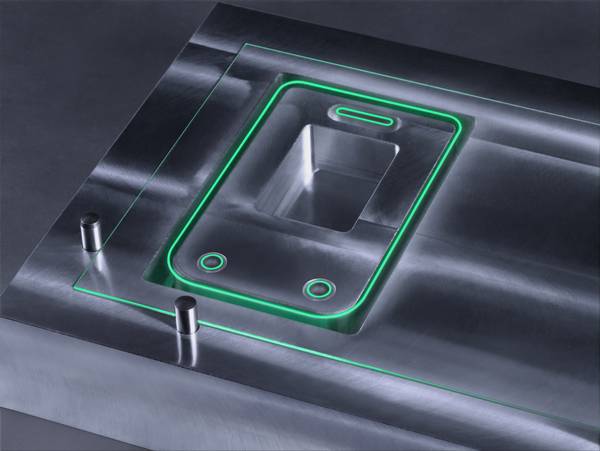

Using ultra-short pulse lasers to cut glass minimizes mechanical stress and does not produce any cracks on the edges. This means it is no longer necessary to grind the components after cutting. Image: TRUMPF