Sandvik has signed an agreement to acquire Almü Präzisions-Werkzeug GmbH (Almü), a Germany-based cutting tools and solutions provider within high-precision drilling, reaming, milling and tooling systems.

With the acquisition of Almü, Sandvik will strengthen its offering towards lightweight components in the automotive segment, an area which is increasing in importance due to the shift towards electric vehicles. The company will be reported in Sandvik Coromant, a division within Sandvik Manufacturing and Machining Solutions.

“Strengthening our position within lightweight materials is one of the key priorities within Sandvik. We have had good progress and made several acquisitions in this area over the past two years, and I am very pleased that we through the acquisition of Almü continue to execute on our strategy,” says Stefan Widing, President and CEO of Sandvik.

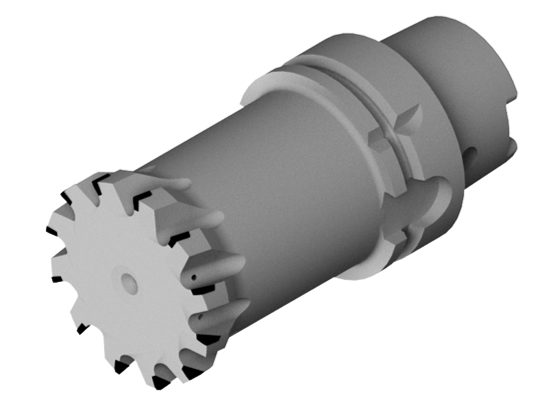

Almü has a strong market position within the DACH region (Germany, Austria and Switzerland) and a solid customer base in the automotive segment. Utilizing its advanced engineering competence and application knowledge for aluminum and lightweight material, Almü provides tailor-made precision tool solutions and services to the machining industry.

Almü was founded in 1978, has 44 employees, and is headquartered in Zell unter Aichelberg, Germany. In 2022, the company generated revenues of about approximately 6 MEUR. The impact on Sandvik’s EBITA margin and earnings per share will be limited. The transaction is expected to close during the second quarter of 2024 and is subject to customary closing conditions. The parties have agreed not to disclose the purchase price.

Contact Details

Related Glossary Terms

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.