Industry News

06/12/2024

PTG Holroyd hosted an event at its Rochdale, United Kingdom, facility during which it gavew a sneak preview of its soon-to-be-launched, large-capacity HG500 ultra-high-performance helical profile grinding machine,

06/11/2024

Lyndex-Nikken, manufacturer of machine tool accessories, has expanded its sales team to "better serve the evolving needs of industry in the U.S. and Canada," the company said.

06/10/2024

3D scanning and optical tracking solutions powered by Verisurf Software.

06/07/2024

AP&T has received an order for a new, fully automatic press line for NKC Sweden’s production facility in Gothenburg. The line will be used to manufacture various types of blanks for spherical bearing housings.

06/06/2024

National Manufacturing Co., a Piscataway, New Jersey-based provider of specialty deep and shallow drawn stamping, was acquired by Chicago-based CORE Industrial Partners, according to a Tuesday announcement from the company.

06/05/2024

ASPINA Inc. has relocated its corporate headquarters to Irvine, California. This move. the company says, represents a significant milestone for ASPINA as it positions the company for continued growth and innovation.

06/04/2024

ABB announced the appointment of Giampiero Frisio as the new President of its Electrification Business Area and Brandon Spencer as the new President of its Motion Business Area. Both will take over their new roles and join ABB’s Executive Committee on August 1, 2024.

06/03/2024

Explore integrated solutions that make manufacturing more efficient at Zoller Inc.'s 2024 Open House and Technology Days.

05/30/2024

Big Daishowa has made several personnel changes to support the company’s strategic initiatives.

05/29/2024

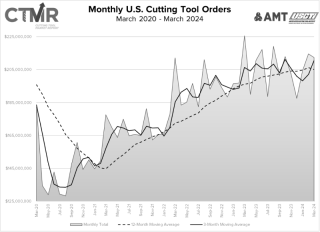

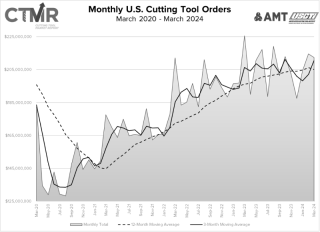

March 2024 U.S. cutting tool consumption totaled $212.4 million, according to the U.S. Cutting Tool Institute (USCTI) and AMT – The Association For Manufacturing Technology.

05/28/2024

Sandvik Coromant, a supplier of cutting tools, machining solutions, and advanced manufacturing knowledge, will showcase an expanded offering of technology and services at the International Manufacturing Technology Show (IMTS) held Sept. 9-14 in Chicago.

05/27/2024

General Carbide Corp., a vertically integrated manufacturer of finished tooling, wear parts, and components for customers in more than two dozen market segments, held its Third Annual Career Signing Day event at which eight students from four local school districts signed letters of commitment for employment at the Greensburg, Pennsylvania, company.

05/24/2024

At IMTS 2024, ANCA CNC Machines is celebrating its anniversary and showing new and upgraded technologies, including its new high-precision tool grinder, the MicroX ULTRA, and the next generation of integrated manufacturing technology, AIMS Connect.

05/23/2024

Hypertherm Associates, a U.S.-based manufacturer of industrial cutting products and software, is gearing up for FABTECH Canada 2024, a metal forming, fabricating, welding and finishing event.

05/22/2024

Accumold will display examples of "impossibly small and intricate parts" that it has developed for medical device OEMs over its nearly 40-year history at the upcoming MD&M South event on booth 1911, June 4-6, in Charlotte, North Carolina.

05/21/2024

Jergens will present its expanded range of modular quick-change workholding solutions and automation capabilities at the International Manufacturing Technology Show. Featured products will include the company’s range of 5-axis vises and top tooling, cast iron tooling columns, Zero Point System, low profile clamping, and Quick-Loc (QL Combo) pallets.

05/21/2024

PTSolutions, a leading provider of industrial solutions based in Novi, Michigan, on May 20 announced an exclusive cutting tooling partnership with the National Tooling & Machining Association (NTMA), a prominent organization in the tooling and machining industry. This collaboration aims to deliver exceptional benefits to NTMA members, including discounts on cutting tools, services and support.

05/20/2024

At IMTS 2024, KUKA Robotics will demonstrate a variety of special automated solutions from several of its system partners that streamline part processing and boost overall production output.

05/17/2024

Unisig will showcase its comprehensive portfolio of deep hole drilling solutions in booth 339159 at IMTS 2024, Sept. 9 – 14, in Chicago.

05/16/2024

Continuing a global relationship that spans more than 20 years, eight-year Kuka Strategic Partner Engel, a leader in plastic injection molding machines, technologies and turnkey solutions, has become a Kuka Robotics System Partner.