Padded reamers are utilized throughout the manufacturing industry to generate the final hole geometry and meet demanding surface finish tolerances. Some examples of padded reamer applications are automatic transmission valve channels, engine valve guides and engine crankbore/cambores. Because the reaming process is one of the

last manufacturing steps prior to assembly, it is extremely important to optimize the process to reduce costly scrap.

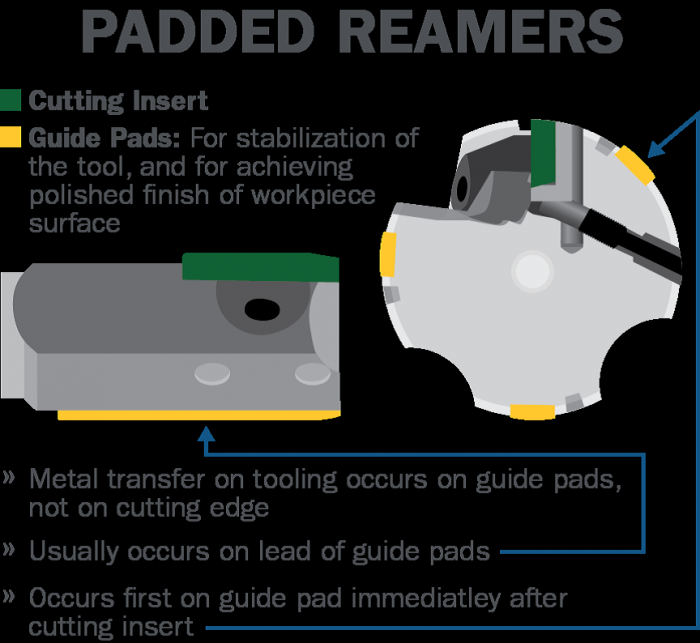

As the name implies, the padded reamer differs from a fluted reamer in that the padded reamer has a cutting surface and guide pads that ride on the diameter of the hole to put pressure on the cutting surface, which generates the hole size and geometry. The guide pads also act as a burnishing tool to help provide a smooth surface finish. Because the pad forces are “riding” on the inside surface of the hole, significant lubrication is necessary in padded reamer operations to eliminate scratches on the hole surface and maintain the required surface finish. Lubrication

is especially critical for the first guide pad after the cutting surface. Therefore, metalworking fluids play a critical role in the optimization of padded reamer applications for the following reasons:

♦ Metal adhesion to the reamer pads is one of the primary routes to failure and loss of surface finish:

-- Inadequate lubrication of the padded reamer may result in scratches in the bore from aluminum pick-up on the guide pads leading to surface finish issues. The primary purpose of the metalworking fluid is to supply a sufficiently thick film to maintain low friction between the workpiece and the guide pad surfaces. This film prevents metal adhesion and subsequent surface finish degradation

♦ Fines from the cutting operation have been shown to be a significant mechanism of failure in the

padded reaming operation:

-- Chips and fines need to be efficiently carried to the filtration system for removal from the machining process. Significant fines build-up will be carried into the guide pad/metal interface and negatively impact the surface finish

♦ Optimal metalworking fluids for padded reamers need to provide lubrication of the guide pads but also carry the fines from the point of cut. These properties are inversely related because more lubrication means an “oilier” emulsion and this typically carries more fines. A “tighter” emulsion typically carries fines more effectively but lacks the lubrication necessary at the pad/metal interface.

♦ Inadequate cooling at the point of cut can result in nonconforming hole geometry and premature reamer wear.

♦ Many reamer applications utilize through-the-tool coolant systems that require a metalworking fluid to operate at higher pressures without foaming. Excessive foaming will adversely affect the coolant pumps and reduce the coolant delivery to the point of cut.

Although proper set-up up of the padded reamer is one of the most critical steps in the success of the reaming process, the proper selection of a metalworking fluid is crucial. Padded reaming requires a metalworking fluid that offers the necessary lubrication properties to give sufficient film thickness and emulsion properties to that will efficiently carry fines, help minimize defects, maximize throughput and increase tool life. Quaker’s high-performance

semisynthetic fluid technology designed for critical reaming applications, QUAKERCOOL 7450,

reportedly provides excellent tapping performance in heavy-duty machining operations such as on automotive

and aerospace-grade aluminum alloys. This fluid delivers significant improvements in reaming applications at

product concentrations lower than typical soluble oil technology. QUAKERCOOL 7450 offers the following

benefits to your operation:

♦ Unique formulation provides the necessary lubrication at the pad/metal interface for critical surface finish requirements while also maintaining extremely efficient fines handling for enhanced padded reamer performance.

♦ Contains excellent foam and emulsion stability properties for high pressure through-the-tool coolant reamer applications.

♦ Insures proper metalworking fluid delivery to the point of cut.

♦ Can be run at water hardness ranges from 0 ppm to 500 ppm and is very stable with increasing magnesium hardness from machining aluminum castings.

♦ Enhanced biostability package resists bacteria and fungus, extends sump life, and has minimal plant odors.

♦ Formaldehyde and boron free technology improves residue and meets HSE compliance.

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- aluminum alloys

aluminum alloys

Aluminum containing specified quantities of alloying elements added to obtain the necessary mechanical and physical properties. Aluminum alloys are divided into two categories: wrought compositions and casting compositions. Some compositions may contain up to 10 alloying elements, but only one or two are the main alloying elements, such as copper, manganese, silicon, magnesium, zinc or tin.

- burnishing

burnishing

Finishing method by means of compressing or cold-working the workpiece surface with carbide rollers called burnishing rolls or burnishers.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- emulsion

emulsion

Suspension of one liquid in another, such as oil in water.

- hardness

hardness

Hardness is a measure of the resistance of a material to surface indentation or abrasion. There is no absolute scale for hardness. In order to express hardness quantitatively, each type of test has its own scale, which defines hardness. Indentation hardness obtained through static methods is measured by Brinell, Rockwell, Vickers and Knoop tests. Hardness without indentation is measured by a dynamic method, known as the Scleroscope test.

- metalworking

metalworking

Any manufacturing process in which metal is processed or machined such that the workpiece is given a new shape. Broadly defined, the term includes processes such as design and layout, heat-treating, material handling and inspection.

- reamer

reamer

Rotating cutting tool used to enlarge a drilled hole to size. Normally removes only a small amount of stock. The workpiece supports the multiple-edge cutting tool. Also for contouring an existing hole.

- tapping

tapping

Machining operation in which a tap, with teeth on its periphery, cuts internal threads in a predrilled hole having a smaller diameter than the tap diameter. Threads are formed by a combined rotary and axial-relative motion between tap and workpiece. See tap.