The Occupational Safety and Health Administration (OSHA) has issued a final rule to prevent chronic beryllium disease and lung cancer in U.S. workers by limiting their exposure to beryllium and beryllium compounds. The rule contains standards for general industry, construction and shipyards.

Annually, OSHA estimates, the rule will save 94 lives from beryllium-related diseases and prevent 46 new cases of chronic beryllium disease—once the effects of the rule are fully realized. The rule is projected to provide annual net benefits of more than $560 million.

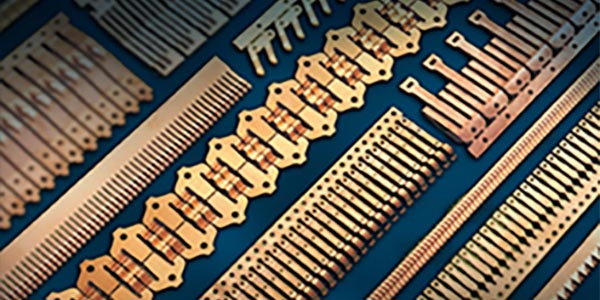

About 62,000 workers are exposed to beryllium in their workplaces, including approximately 11,500 construction and shipyard workers who may conduct abrasive blasting operations using slags that contain trace amounts of beryllium. The majority of workers affected by this rule are exposed in general industry operations such as beryllium metal and ceramic production, non-ferrous foundries, and fabrication of beryllium alloy products. Responsible employers have been protecting workers from harmful exposure to beryllium for years, using engineering and work practice controls along with personal protective clothing and equipment.

Key Provisions:

- Reduces the permissible exposure limit (PEL) for beryllium to 0.2 micrograms per cubic meter of air, averaged over 8-hours.

- Establishes a new short term exposure limit for beryllium of 2.0 micrograms per cubic meter of air, over a 15-minute sampling period.

- Requires employers to: use engineering and work practice controls (such as ventilation or enclosure) to limit worker exposure to beryllium; provide respirators when controls cannot adequately limit exposure; limit worker access to high-exposure areas; develop a written exposure control plan; and train workers on beryllium hazards.

- Requires employers to make available medical exams to monitor exposed workers and provides medical removal protection benefits to workers identified with a beryllium-related disease.

All three standards contained in the final rule take effect on March 10, 2017, after which all three sectors have one year (March 12, 2018) to comply with most of the requirements. All sectors have two years (March 11, 2019) from the effective date to provide any required change rooms and showers and three years (March 10, 2020) from the effective date to implement engineering controls.

The final rule replaces a 40-year-old permissible exposure limit (PEL) for beryllium that was outdated and did not adequately protect worker health. OSHA formally asked for public input on a possible beryllium rule in 2002, and rulemaking specialists visited work sites, performed risk assessments and calculated potential impacts on small businesses. In 2012, the effort received a boost when a major beryllium manufacturer and a labor union representing many beryllium workers jointly submitted a model for a new rule.

OSHA issued a proposed rule in 2015, followed by a months-long public comment period and several days of public hearings. The final rule reflects input from industry and labor stakeholders, small business representatives, subject matter experts and partner agencies.

Related Glossary Terms

- abrasive

abrasive

Substance used for grinding, honing, lapping, superfinishing and polishing. Examples include garnet, emery, corundum, silicon carbide, cubic boron nitride and diamond in various grit sizes.