Article provided by Ingevity

Diacid 1550 is a bio-based emulsifier with a growing reputation among metalworking fluid formulators worldwide. Because of its ability to create a more stable metalworking fluid and provide corrosion inhibition, Diacid is a trusted addition to formulations used to machine super alloy metals. This means that customers can expect precision even in the high-heat and high-pressure environments of jet and rocket engine manufacturing. That’s The Ingevity Effect.

Problem

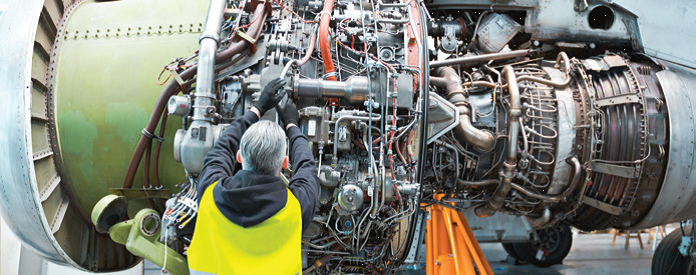

Federal regulations to increase the fuel efficiency of jet and rocket engines continue to become more demanding. Protomatic Inc., Dexter, Mich., a manufacturer of space vehicle components for Blue Origin, is all too familiar with the challenges of continuous innovation while meeting these demands. The high-performance, superalloy metals required to manufacture today’s rocket engines mean that Protomatic needs a state-of-the-art, multifunctional machining coolant.

“The super alloy metals we use to make these massive rocket engines are more difficult to cut,” explained Doug Wetzel, vice president and general manager at Protomatic. “They also require higher heat, pressure and lubricity in order to be cut with the desired precision. We use Ingevity’s additive in our coolant formulation because it works well in this harsh environment.”

Solution

The value of Diacid 1550 is becoming increasingly well known to even the most demanding metalworking fluid formulators worldwide. Protomatic’s material selection process for additives used in their machining coolant formulation is strict: The additive must be compatible with both the metal alloys and the cutting tools; it must have high lubricity at cutting temperatures; it must extend the life of the tools and the overall life of the coolant; and it must be worker friendly in terms of look, smell and feel. Diacid has enabled Protomatic to make a difficult manufacturing environment much less complicated.

Maximizing Value

♦ Diacid 1550’s dual action functionality and higher affinity for metal surfaces creates a chemical protective barrier, which means increased corrosion inhibition.

♦ The unique molecular structure of Diacid 1550 means more stability in fluid compositions for metalworking fluid formulators.

♦ Diacid 1550 can reduce the amount of emulsifier additives and corrosion inhibitors required in formulation, which saves money.

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- lubricity

lubricity

Measure of the relative efficiency with which a cutting fluid or lubricant reduces friction between surfaces.

- metalworking

metalworking

Any manufacturing process in which metal is processed or machined such that the workpiece is given a new shape. Broadly defined, the term includes processes such as design and layout, heat-treating, material handling and inspection.