Sometimes manufacturing can feel like a battle between David and Goliath. But in the era of automation, think Industry 4.0, manufacturers are discovering the advantages to being smaller. Automation technology has leveled the playing field and now smaller means nimble, niche and, for the first time, heading in the same direction as the big guys.

New technology means that smaller businesses have access to a huge amount of capability that may have been too large an investment in the past to consider. Automation also reduces the cost of manufacturing meaning companies don’t need a huge turn over to be viable and competitive. The networking of older machines can be achieved at relatively low cost and the production benefits can be huge.

Photos courtesy of ANCA

Leveling the playing field

A report by Deloitte shows high-performing manufacturers outperform their competition not because they’re bigger, but because they leverage: brand and reputation, new markets and customers, and advancing technology.

Let’s have a look at how to use available networking and automation technology so your business can match or exceed the quality and productivity of the established giants.

- Focus on quality

- Break down the experience barriers

- Increase production (yes, it’s possible)

- Harness automation for your own production boom

- Shout from the top of the internet

Focus on quality

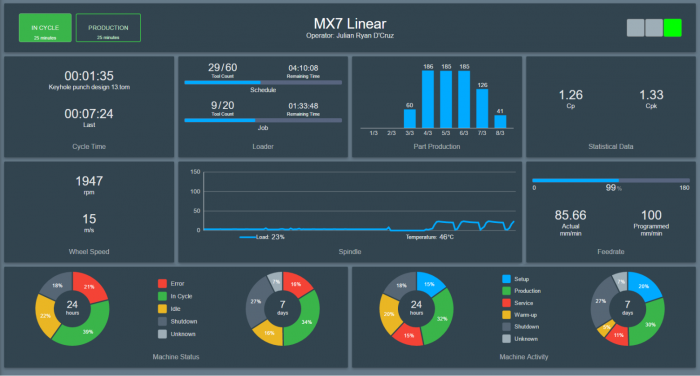

We know that at the end of the day it’s really not age or size that matters. It’s the quality of your grinding. This is where the big advantage is for smaller companies. When it comes to tool manufacturing it’s quality that speaks loudest. Smaller companies are able to run production, which automatically measures and corrects tool grinding precision, to ensure that your accuracy is no less than the very best.

Break down the experience barriers

Not sure you have the experience under your belt to specialise? The right software can fix that. Now, if you have the right machine and the right software, you can grind a wide variety of tools without having specialist knowledge about them, or previous experience with that tool type.

In terms of competition; the good news is that larger tool companies aren’t as interested in specializing. They’re after the big volume or catalog production, leaving plenty of opportunity for you to swoop in and get the niche clients.

Increase production (yes, it’s possible)

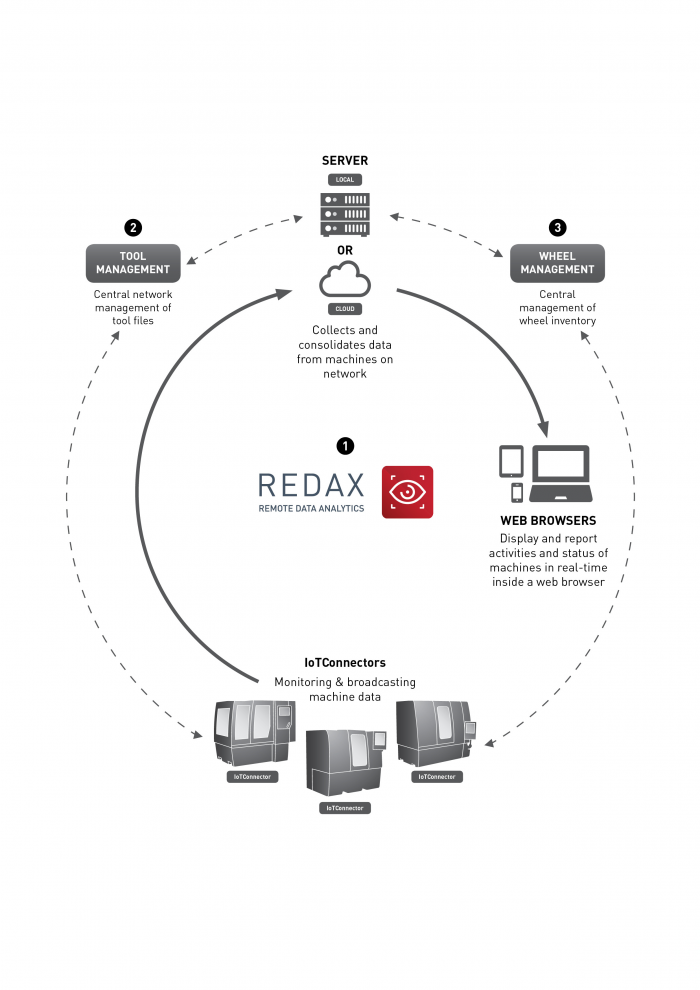

Even though you’re smaller, automation can really boost your production output. Long gone are the (long) days where machines must be manned all the time, and all the weekend. By networking and automating your existing systems you can run 24 hours a day, 7 days a week in lights-out mode.

Harness technology for your own production boom

Not only can production be automated but your whole process can benefit from machine networking. Integrate your ordering, invoicing and dispatch to reduce administration and allow flexible work. You’ll gather insights into your whole process from end to end, making it faster for you to adapt and change to different market pressures. With a finger on the pulse of your production, you can optimize it and watch it take off.

Shout from the top of the internet

As Deloitte said, it’s not just the manufacturing technology that can be your competitive edge. The internet as a marketing tool is another great leveler. Smaller companies can also use the power of the internet to compete from a marketing and brand reputation perspective. You can use low-cost online activities like social media, or create a presence in online forums to build your reputation. The tool and grinding community is heavily networked and the more you get your name out there, the more people will be talking about you – no matter how big you are.

There are definitely specific challenges that will always face smaller manufacturers. Smaller businesses can't access volume discounts on materials, they can't produce as much volume, they have less money to invest in R&D and they have a smaller operating area and often lower brand awareness. The most effective way to build your brand is by delivering premium service – designing and dispatching tools swiftly at the best quality.

On the flip side the availability of machine networking and automation technology means small manufacturers can make their mark in niche areas. They can specialize where the big guys can’t or won’t go, operate lights out to increase their output and leverage the power of the internet to spread the word.

Goliath should be worried.

Related Glossary Terms

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.