By Tim Aydt, indexable milling product manager, Seco Tools LLC

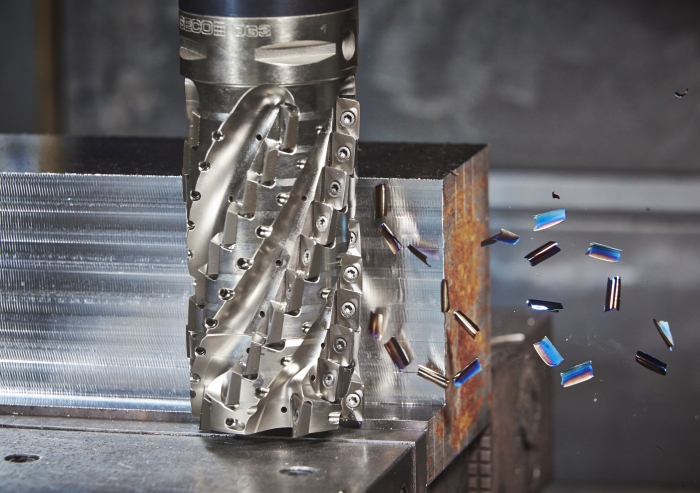

When it comes to achieving high material-removal rates in even the toughest materials, it’s hard to beat helical cutters. With the correct insert grades and cutting data, these cutters can achieve far greater depths of cut than non-helical milling tools without sacrificing reach or the ability to hold tolerance. This means higher rates of metal removal at speeds that reduce the time the inserts spend in-cut, simultaneously minimizing cycle times and maximizing tool life.

Photos courtesy of Seco Tools

For demanding industries like automotive and aerospace, custom helical cutters can transform processes for even the most difficult applications. In materials ranging from heat-resistant superalloys to aluminum, helical cutters can easily outpace nonhelical designs, and custom versions of the tools can be shaped to fit the required application. However, demanding industries often have equally demanding schedules, and while custom tool manufacturers strive to meet customers’ needs as quickly as possible, the turnaround time for a custom product can be prohibitive when there are parts to cut.

Despite that disadvantage, there are a myriad of reasons to choose helical cutters. In one example from the aerospace industry, a custom helical cutter used for machining landing gear torque links paid for itself within months. Made from Ti5553, a heat-treated titanium alloy, the part was previously machined using a high-feed milling strategy that required 84 passes. With a custom helical solution, that number was reduced to only four passes with a 1.25” DOC.

Given the massive reduction in the number of passes, one might expect a slower process. However, the helical cutter provided six times the tool life of the high-feed mill and a 40 percent increase in metal-removal rate. The result was a cycle time reduction of 60 percent, which, over the course of a year of machining, created more than $40,000 in savings.

Aerospace manufacturers have duplicated these results across their industry. Another manufacturer utilized custom helical tooling for the production of landing gear truck beams, the critical component that links the axles and holds the brake rods. When compared to the previous solution the company used, the custom helical solution provided 40 percent increases in speed and metal-removal rate. Furthermore, the insert wear was much more predictable thanks to the improvements to the process, extending tool life by three times over the previous solution.

This increase in tool life also has significant downstream effects. The time spent indexing inserts or stopping machining for mid-process tool changes obviously drops when tools last longer. This frees a machine’s operator to work on something more productive and reduces machine downtime. Likewise, tooling manufacturers can also offer replaceable end caps with custom helical cutters, which make it simple to replace the front rows of a cutter far more cost-effectively than the alternative: buying a completely new cutter or having the broken cutter repaired.

These exceptional results are due in part to insert grade selection – the correct grade ensures the highest possible feed per tooth, a major factor in metal removal rate. F40M, a titanium aluminum nitride (TiAlN) coating, is perfect for inserts cutting parts such as torque links, while T350M, a titanium carbonitride (TiCN) coating, is ideal for parts like the truck beams in the example above.

Recently, Seco has produced several grades designed for the challenging cutting conditions created by titanium and high-temp alloys like Ti5553. One newer grade, MS2050, features a niobium nitride (NbN) coating that significantly increases lubricity. Meanwhile, the exceptionally tough MS2500 can reach higher speeds than other grades due to an aluminum oxide (Al2O3) top layer produced via chemical vapor deposition (CVD), which makes for a highly wear-resistant grade.

While insert selection plays a critical part in process optimization, the custom helical cutters themselves played a starring role in the examples from the aerospace industry. Conversely, automotive manufacturers rarely need to reach the levels of tolerance required in the aerospace industry. Instead, they rely on the cutting geometries of helical mills to reduce cycle times in high-volume applications. With long effective cutting edges paired with aggressive insert geometries and placement, these cutters can even outperform competitors with helical interpolation, ramping and other advanced milling techniques in addition to standard operations.

For many manufacturers, these advantages mean little due to time considerations – regardless of industry, few shops can afford the time their tooling suppliers need to quote, design, produce and deliver a custom tool. Luckily, Seco has a solution: a semistandard helical cutter program that streamlines the process by eliminating numerous time-consuming steps. The result is an average reduction in turnaround time of 50 percent, from over 60 days to as few as 30.

The creation of a turnkey helical cutter solution revolves around semistandardization. Standard tooling, like any line of standardized products, rarely works perfectly for any given application, but long experience has shown what types of tools manufacturers use most often. A fully optimized process naturally requires fully optimized tooling, and custom products have traditionally been the only way to achieve these benefits.

The semistandard helical cutter program succeeds in finding the happy medium between these types of tools. Seco’s program draws on the company’s long history of creating custom products to identify a range of helical cutter solutions that its customers most often request. Rather than quote and design each product individually, the program allows manufacturers to receive an instant price quote on well-understood designs, a major factor in reducing lead time.

By starting from a semistandard design, the rest of the process is much easier to optimize as well. Custom products often require significant time spent on design and subsequent approval, both of which can be accomplished much more quickly when the bulk of the design work has already been completed. Likewise, semistandard designs make it far easier to create optimal cutting programs, allowing for much faster production of complex helical cutters.

Naturally, a semistandardized line of products cannot serve as a substitute for a fully custom cutter. Your tooling manufacturer should be able to meet these needs with dedicated custom products and process optimization teams, which are capable of engineering complete solutions for even highly complex applications. These services require much more time, but these teams have the ability to take a deep dive into a process and design a tool around it. For the majority of metalcutting operations, however, a semistandard helical cutter will be all a shop needs to positively impact its bottom line – all in less than half the time it took before.

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- aluminum oxide

aluminum oxide

Aluminum oxide, also known as corundum, is used in grinding wheels. The chemical formula is Al2O3. Aluminum oxide is the base for ceramics, which are used in cutting tools for high-speed machining with light chip removal. Aluminum oxide is widely used as coating material applied to carbide substrates by chemical vapor deposition. Coated carbide inserts with Al2O3 layers withstand high cutting speeds, as well as abrasive and crater wear.

- chemical vapor deposition ( CVD)

chemical vapor deposition ( CVD)

High-temperature (1,000° C or higher), atmosphere-controlled process in which a chemical reaction is induced for the purpose of depositing a coating 2µm to 12µm thick on a tool’s surface. See coated tools; PVD, physical vapor deposition.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- helical cutter

helical cutter

Endmill or other cutter with spiral or helical flutes. May be right- or left-hand.

- interpolation

interpolation

Process of generating a sufficient number of positioning commands for the servomotors driving the machine tool so the path of the tool closely approximates the ideal path. See CNC, computer numerical control; NC, numerical control.

- lubricity

lubricity

Measure of the relative efficiency with which a cutting fluid or lubricant reduces friction between surfaces.

- metal-removal rate

metal-removal rate

Rate at which metal is removed from an unfinished part, measured in cubic inches or cubic centimeters per minute.

- metalcutting ( material cutting)

metalcutting ( material cutting)

Any machining process used to part metal or other material or give a workpiece a new configuration. Conventionally applies to machining operations in which a cutting tool mechanically removes material in the form of chips; applies to any process in which metal or material is removed to create new shapes. See metalforming.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- superalloys

superalloys

Tough, difficult-to-machine alloys; includes Hastelloy, Inconel and Monel. Many are nickel-base metals.

- titanium aluminum nitride ( TiAlN)

titanium aluminum nitride ( TiAlN)

Often used as a tool coating. AlTiN indicates the aluminum content is greater than the titanium. See coated tools.

- titanium carbonitride ( TiCN)

titanium carbonitride ( TiCN)

Often used as a tool coating. See coated tools.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.