Richfield, WI – – – Jim White, National Sales Manager of Carmex USA, has announced the opening of a new distribution center to serve the expanding West Coast market. Located at 15571 Chemical Lane in Huntington Beach, California, the center is scheduled to open by the end of October, 2018, and will carry the complete Carmex line. Carmex manufactures a wide selection of high-precision cutting tools with emphasis on thread milling and Swiss-style machining.

Richfield, WI – – – Jim White, National Sales Manager of Carmex USA, has announced the opening of a new distribution center to serve the expanding West Coast market. Located at 15571 Chemical Lane in Huntington Beach, California, the center is scheduled to open by the end of October, 2018, and will carry the complete Carmex line. Carmex manufactures a wide selection of high-precision cutting tools with emphasis on thread milling and Swiss-style machining.

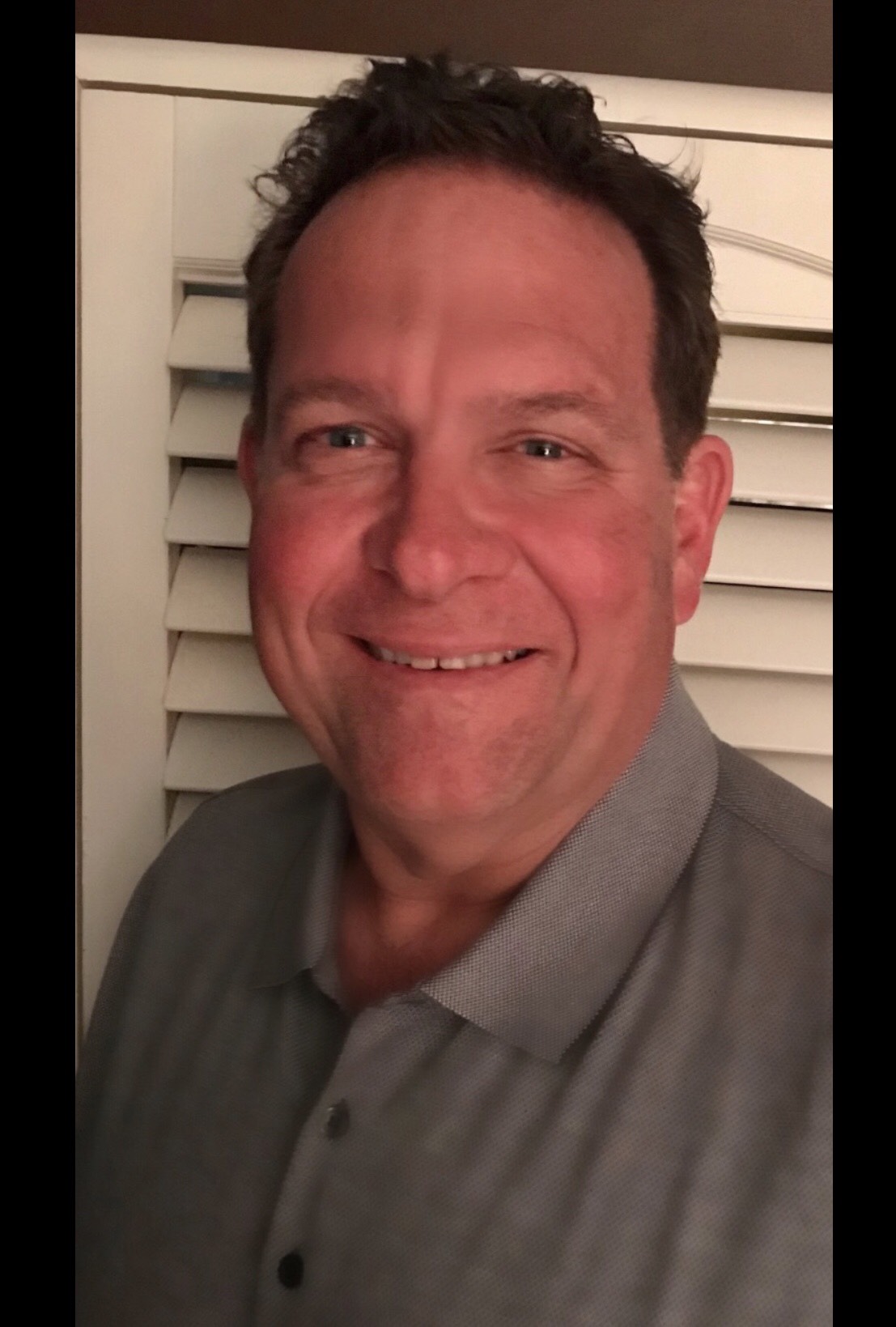

In making the announcement, Jim White commented, “The West Coast and adjoining areas have been especially receptive to the products we sell in terms of both quality and function. The aerospace, defense, medical, energy, and communications sectors have created extremely heavy demand for our tools. As thread milling is rapidly replacing tapping in many areas and the machining of complex small-sized parts has become more prevalent, Carmex’s years of involvement in both areas have provided a source of tooling and assistance to both OEMs and job shops.”

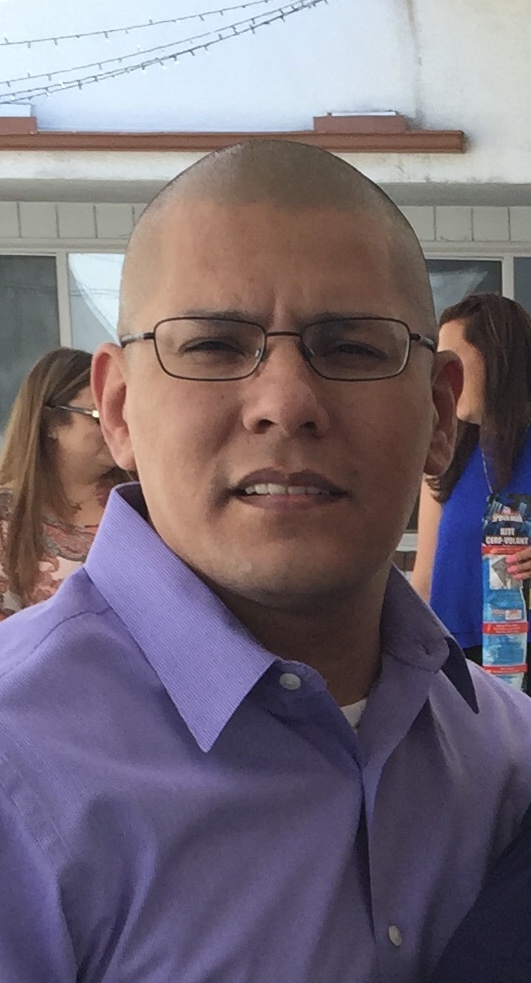

Carmex has also recently added additional support staff to the West Coast area. Jim Casteen, recently appointed Regional Manager, is responsible for the Western US-Denver West. Jim’s background includes assignments on both the customer side and with major tooling manufacturers, including Kennametal and Seco Tools/Sandvik Coromant. A member of the Society of Manufacturing Engineers, ASME, AMTDA, AMT, and ADS, Jim comments, “Thanks to my previous work assignments, I have been able to assist customers with challenging machining applications. I see a great potential for the thorough approach that Carmex brings to both engineering and customer service. In addition to an extensive product line, we have the capability to respond with highly specialized solutions for unique situations. We are totally committed to helping customers achieve top quality and high production.”

Jim Casteen, recently appointed Regional Manager, is responsible for the Western US-Denver West. Jim’s background includes assignments on both the customer side and with major tooling manufacturers, including Kennametal and Seco Tools/Sandvik Coromant. A member of the Society of Manufacturing Engineers, ASME, AMTDA, AMT, and ADS, Jim comments, “Thanks to my previous work assignments, I have been able to assist customers with challenging machining applications. I see a great potential for the thorough approach that Carmex brings to both engineering and customer service. In addition to an extensive product line, we have the capability to respond with highly specialized solutions for unique situations. We are totally committed to helping customers achieve top quality and high production.”

Leonard Ahumada, recently appointed Territory Manager, is responsible for Southern California, Bakersfield South. Ahumada brings wide-ranging experience to the position, having worked on the customer side. He holds NIMS certification in areas including machining measurements, job planning, CNC operation, and CNC programming. Ahumada stated, “Coming from the customer side in the manufacture of high-precision parts, I can understand and anticipate the end-user perspective on tooling needs and systems. I chose to work with Carmex thanks to my first-hand knowledge of the products they make and the support that they provide.”

Jim White states, “As we look toward the future, our enhanced staff and warehouse capabilities will enable us to serve the Western market with a comprehensive tooling catalog, as well as the fastest delivery possible. We look forward to continued growth.”

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- tapping

tapping

Machining operation in which a tap, with teeth on its periphery, cuts internal threads in a predrilled hole having a smaller diameter than the tap diameter. Threads are formed by a combined rotary and axial-relative motion between tap and workpiece. See tap.